Pfannenberg’s Chillers Keep Chocolate Tasting Great

Pfannenberg’s Chillers Keep Chocolate Tasting Great

Chocolate plays a major role in many of our holidays as Valentine’s Day or Easter! Whether it’s a box of chocolates or Easter eggs filled with various sweets – there is an extensive process that goes into making these enjoyable treats!

The manufacturing process of chocolate is a delicate procedure. Temperature control of the equipment and the product is important to producing a flavorful and scrumptious chocolate. All processes related to making chocolates are temperature regulated.

A major aspect of chocolate manufacturing is the conching step. Pfannenbergs’ packaged chillers are an ideal solution for the temperature regulation in this process. Conching is the step in which the chocolate receives its flavor and smooth characteristics! At this stage, the addition of other ingredients is introduced as metal mixers/rollers mix the ingredients together. This step generates its own heat, which is integral to keep the flavor and the proper consistency of the liquid state. This chocolate has to be kept at average of 175°F throughout the process (temperature will vary depending on the type of chocolate). The length of this process will vary depending on the flavor of chocolate. Typically the average time spent conching is between 4-6 hours; gourmet chocolate brands will spend 30+ hours at this stage.

Following conching, the next step in the process is tempering. Tempering gives chocolate a distinctive shine and color; adding additional flavor. It is crucial to have strict temperature control. For tempering, a cooling tunnel is used to take the ambient air; cooling the air to approximately 50°F. The air then needs to be heated to ambient air temperature. Pfannenberg’s process chillers have been used successfully in the production of candy and chocolate. At this stage it is crucial once again for strict temperature control. If the temperature of chocolate begins to harden and then is heated to become a liquid state – the chocolate is ruined. For chocolate to receive its distinct flavor, look, and texture – the temperature of the chocolate and the air it is produced in is critical.

Tempering gives chocolate a distinctive shine and color; adding additional flavor. It is crucial to have strict temperature control. For tempering, a cooling tunnel is used to take the ambient air; cooling the air to approximately 50°F. The air then needs to be heated to ambient air temperature. Pfannenberg’s process chillers have been used successfully in the production of candy and chocolate. At this stage it is crucial once again for strict temperature control. If the temperature of chocolate begins to harden and then is heated to become a liquid state – the chocolate is ruined. For chocolate to receive its distinct flavor, look, and texture – the temperature of the chocolate and the air it is produced in is critical.

Next time you eat a piece of chocolate, be sure to appreciate the process it takes to produce such a sweet indulgence!

>> Click here to discover our complete range of chillers!

By keeping electronics in enclosures from overheating, Pfannenberg provides an invaluable service to companies, keeping their machinery and processes consistently operating. By developing and producing products which are designed to save energy and other resources, Pfannenberg operates by their business philosophy – Protecting man, machine and the environment.

Topics: Cooling Units, North America, Packaged Chillers, Food & Beverage, Chillers

ng table, where the candy has its flavoring added and mixed. The amber liquid when being first mixed is heated up to around 300°F. Once being transferred to the kneading machine, this large machine will mix in the flavoring by pushing and folding the candy – slowly cooling the product from its hot temperature.

ng table, where the candy has its flavoring added and mixed. The amber liquid when being first mixed is heated up to around 300°F. Once being transferred to the kneading machine, this large machine will mix in the flavoring by pushing and folding the candy – slowly cooling the product from its hot temperature.

Tis’ the season – for we have many things to be thankful for this year! With the holiday season quickly approaching, we are taking the time to reflect on all of our blessings. Common dishes for most Traditional American Thanksgivings include turkey, cranberry sauce, stuffing, green bean casseroles, fresh baked rolls, and pumpkin pie. Most of us look forward to this holiday all year, for it is a time to be thankful and gather with loved ones.

Tis’ the season – for we have many things to be thankful for this year! With the holiday season quickly approaching, we are taking the time to reflect on all of our blessings. Common dishes for most Traditional American Thanksgivings include turkey, cranberry sauce, stuffing, green bean casseroles, fresh baked rolls, and pumpkin pie. Most of us look forward to this holiday all year, for it is a time to be thankful and gather with loved ones. When it comes to the vacuum packing machines they operate at very high speeds, processing many turkeys in a short amount of time. It’s critical that the control enclosure electronics do not overheat. Proper cabinet temperature control is essential to keeping production on schedule. To keep these electrical enclosures cool, the processing facility has several options. If using traditional enclosure air conditioners (cooling units) then our washdown NEMA Type 4/4x

When it comes to the vacuum packing machines they operate at very high speeds, processing many turkeys in a short amount of time. It’s critical that the control enclosure electronics do not overheat. Proper cabinet temperature control is essential to keeping production on schedule. To keep these electrical enclosures cool, the processing facility has several options. If using traditional enclosure air conditioners (cooling units) then our washdown NEMA Type 4/4x

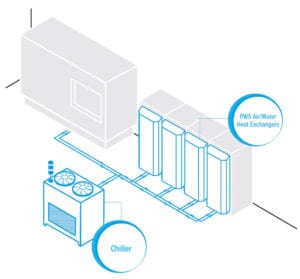

With manufacturing space at minimum, machine packages have become smaller and liquid cooling has emerged as the most efficient and economical means of removing process heat. Chillers often are the only method of providing sustainable efficiency & reliability performances in “hostile” environments.

With manufacturing space at minimum, machine packages have become smaller and liquid cooling has emerged as the most efficient and economical means of removing process heat. Chillers often are the only method of providing sustainable efficiency & reliability performances in “hostile” environments. It is recommended to use a Water-Glycol

It is recommended to use a Water-Glycol

Cooling with oil is dedicated to very specific applications in which the process liquid is an oil or an emulsion with a high viscosity. Pfannenberg’s EB Chillers allow the maximum cooling capacity in the smallest possible footprint.

Cooling with oil is dedicated to very specific applications in which the process liquid is an oil or an emulsion with a high viscosity. Pfannenberg’s EB Chillers allow the maximum cooling capacity in the smallest possible footprint. Whatever your industry, selecting the best packaged chillers to meet the demanding requirements of your industrial applications can be complicated.

Whatever your industry, selecting the best packaged chillers to meet the demanding requirements of your industrial applications can be complicated.

The first step into creating one of the most loved foods is the preparation of the meat. The meat is cut into small pieces and is placed into a large mixer. These mixers have chopping blades to further cut the meat into smaller sizes. Here the raw ingredients and flavorings are added. All are mixed until the mixture is a smooth paste consistency. Processes like this can require large control panels to operate the system and

The first step into creating one of the most loved foods is the preparation of the meat. The meat is cut into small pieces and is placed into a large mixer. These mixers have chopping blades to further cut the meat into smaller sizes. Here the raw ingredients and flavorings are added. All are mixed until the mixture is a smooth paste consistency. Processes like this can require large control panels to operate the system and  Once the smoking is completed, the link casings are removed by an automatic peeler. During this time, the hot dogs are sprayed with water to help bring down their temperature. Then the hot dogs are then transported to be packaged. Before going into the final packaging, the hot dogs are inspected to make sure there are no foreign ingredients in the product.

Once the smoking is completed, the link casings are removed by an automatic peeler. During this time, the hot dogs are sprayed with water to help bring down their temperature. Then the hot dogs are then transported to be packaged. Before going into the final packaging, the hot dogs are inspected to make sure there are no foreign ingredients in the product.

With the next round of

With the next round of  Pfannenberg worked directly with a food and beverage inspection OEM to provide complete engineering solutions for the cooling of x-ray tubes and the internal cavity of their inspection machines. These machines would end up in various food & beverage and pharmaceutical end use facilities. Before meeting with Pfannenberg our customer used several different competing thermal management products; conventional cabinet air conditioners to cool the machine cavity, two small internal fans to move the air around and a small chiller. It was costly, cumbersome while leading to additional maintenance costs and condensate issues.

Pfannenberg worked directly with a food and beverage inspection OEM to provide complete engineering solutions for the cooling of x-ray tubes and the internal cavity of their inspection machines. These machines would end up in various food & beverage and pharmaceutical end use facilities. Before meeting with Pfannenberg our customer used several different competing thermal management products; conventional cabinet air conditioners to cool the machine cavity, two small internal fans to move the air around and a small chiller. It was costly, cumbersome while leading to additional maintenance costs and condensate issues.