The Elements of Effective Signaling for Industrial Safety and Process Control

Industrial signaling is critical to both process control and personnel safety. Horns and strobes are necessary in order to alert workers to hazards such as gas accumulation and machine failure. They are only effective, however, if they are bright enough to be seen and loud enough to be heard. The right industrial alarm can cut through the noise of heavy industry, but it is important to know the ambient sound level, as well as the maximum sound level, to determine the right decibel level for a given area.

Determine the required safety level for your specific industry

Despite the crucial role that signaling technologies play in protecting employees, many companies still look strictly at minimum standards. With so much at stake, operators need to set a higher standard. Once they determine the required safety level for a specific manufacturing environment, operators can ask a range of questions to arrive at the right signaling devices that best protect their workers, normalize the flow of process conditions, and mitigate overall risk.

Industrial signaling includes audible signaling, visual signaling, and combined audible/visual signaling devices. With so many different aspects of signaling to consider, answering the following questions can effectively lead designers toward the ideal signaling technologies for any intended environment:

- What must you accomplish with the signal? An alarm? An evacuation notice?

- What potential hazards prompt you to install the signaling device?

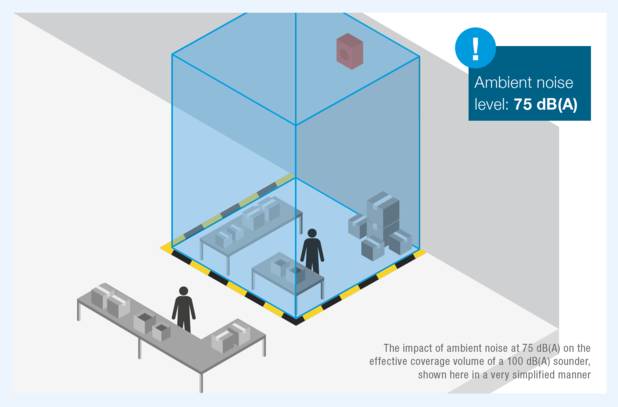

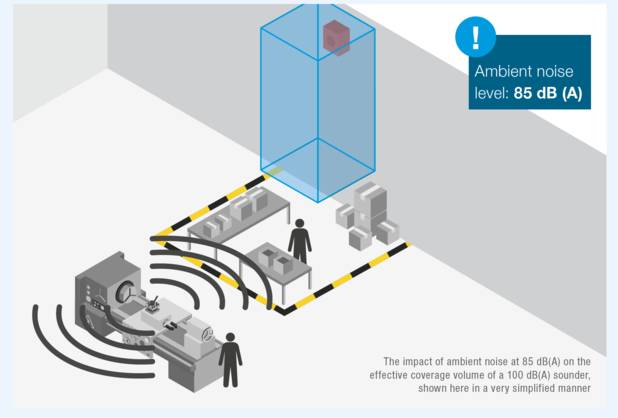

- How loud is the ambient noise in the intended work environment?

- Within what area around a machine will people be able to hear an alarm or see a strobe?

- How far does sound travel in the intended space?

- What personnel are in the room and where are they located vis a vis the alarm or strobe?

Addressing these concerns provides a good first step towards ensuring safety. However, meeting alarm specifications such as decibels (sound) or lumens (light) is not enough to guarantee the required response by personnel. In order to be effective in alerting personnel, one must consider the following three indispensable dimensions:

The personnel dimension:

The location of personnel with regards to the safety of being notified by a signaling device.

The location of personnel with regards to the safety of being notified by a signaling device.

This includes restrictions due to ear and eye protection.

The special conditions dimension:

Unique factors in the surrounding environment that could affect whether someone hears or sees an alarm and the life of the alarm’s operation.

Unique factors in the surrounding environment that could affect whether someone hears or sees an alarm and the life of the alarm’s operation.

The spatial dimension:

The element that determines the actual effective coverage volume for audible and visual signaling devices. Not just decibels and lumens, but the way sound and light travel through space.

The element that determines the actual effective coverage volume for audible and visual signaling devices. Not just decibels and lumens, but the way sound and light travel through space.

Pfannenberg “3D-Coverage” for your alarm notification planning

Pfannenberg’s innovative “3D-Coverage” does not overlook these considerations. For example, Pfannenberg retrofitted a wastewater treatment facility in Tonawanda, NY with chlorine gas alarms. The previous system required 50 devices to cover the facility. Using the 3D approach, Pfannenberg put together a design that integrated its PATROL® and PYRA® systems.

Pfannenberg’s innovative “3D-Coverage” does not overlook these considerations. For example, Pfannenberg retrofitted a wastewater treatment facility in Tonawanda, NY with chlorine gas alarms. The previous system required 50 devices to cover the facility. Using the 3D approach, Pfannenberg put together a design that integrated its PATROL® and PYRA® systems.

These achieved a higher level of coverage with only 20 devices, saving the facility money while simultaneously improving its safety. When it comes to signal processing, Pfannenberg’s 3D coverage brings the vision that can help you find the right approach for both your workplace and your personnel.

Coverage example depending on the ambient level: