PKS 3000 Series Air To Air Heat Exchangers

Next Generation Cooling for Electrical Enclosures

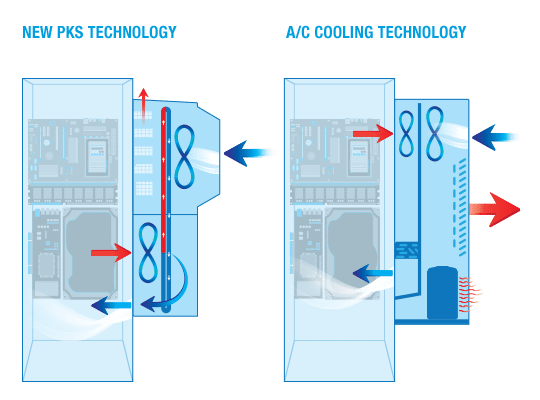

Pfannenberg’s PKS 3000 Series Air to Air Heat Exchangers use a revolutionary next generation cooling technology that out-performs conventional heat exchangers and/or heat pipe solutions. One of the best technologies to use when there is a temperature difference between the internal target temperature and the surrounding temperature (∆T≥10°C) is air to air technology. An air to air heat exchanger removes heat from inside of the enclosure to the cooler environment using the least amount of energy while still providing a closed loop ingress protection.