DTT Range of Top Mounted Cooling Units

Pfannenberg’s DTT Series top mounted cooling units are 100% condensate safe. These units are ideal for space-saving installation on the top of the control cabinet.

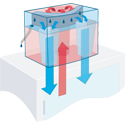

One of the main features of the DTT’s innovative condensate management design is the repositioning of the cooling circuits. Moving the cold area up prevents condensation from forming in the cabinet where the cooling unit meets the enclosure. A widened airflow in the evaporator stops the formation of condensate buildup.

Finally return air channels are engineered to increase the speed of the air leaving the cooling unit, ensuring cool air is effectively distributed moisture-free within the enclosure.

Why Choose Pfannenberg Top-Mounted Cooling Units

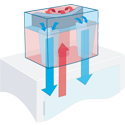

Condensate Build-Up

Condensate Build-Up

The warm air is spread out over a large evaporator. The reduced air speed at the evaporator reduces the risk of water being carried through the air, guaranteeing a condensate-free airflow in the direction of the electrical enclosure.

No Condensate Overflow

No Condensate Overflow

The positioning of the evaporator in the top part of the cooling unit allows for problem free drainage of the condensate water without contact to the electrical enclosure.

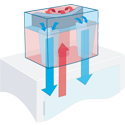

Cold Bridge

Cold Bridge

The position of the air-conditioning circuits was changed. When the cold area of the cooling unit is at the top and the warm area is at the bottom, a “cold bridge” cannot form on the inside ceiling eliminating the risk of condensate dripping inside the electrical enclosure.

Air Hoses

Air Hoses

Integrated nozzles instead of air hoses. Air outlet nozzles are positioned on both sides of the cooling unit which accelerate the cold air and conduct it condensate-free down to the bottom of the electrical enclosure.