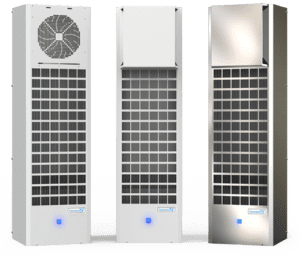

DTS Cooling Units

For Harsh Environments

DTS Cooling Units offer an ideal cooling solution for spindle motors and automation drives in power plant electronics and solar inverters in energy production, and provide superior performance in harsh environments with high temperatures.

Outdoor units have a special coating on pipes and coils to protect from saltwater and other corrosive substances. Top Mount Cooling Units have unique condensate safety feature for cabinets in the tower button or other areas where space is limited.

Offered in NEMA Type 12/3R/4/4X 304 stainless steel, the DTS Cooling Unit utilizes an internal heater which eliminates the need for a drain line, and is coated with special polish to repel contaminants, will seal out the ambient air, and cool and re-circulate clean, cool air.

The DTS Cooling Units closed loop design isolates the external ambient air from the internally conditioned air eliminating the risk of contaminants entering the cabinet. The hermetically sealed compressor guarantees 100% cooling capacity efficiency. The absence of any refrigerant fill valves eliminates leak paths.

Ideal for energy plants, or battery storage and charging stations where:

- Hot and Clean or Hot and Dirty ambient conditions

- -40°C to -60 °C

- NEMA Type 12/3R/4/4X

- Outdoors or heavy spray

- Anywhere that condensate is an issue

Sample Industry Applications:

- Spindle motors and automation drives in power plant electronics

- Solar inverters

- Tower houses

- Power converter cabinets

- Drive trains

Click here to learn more: DTS Cooling Units

Related articles:

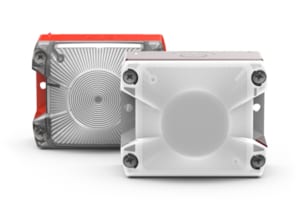

Filterfans®

Trust in the Original

Our patented Filterfans® are an ideal cooling solution in areas manufacturing plants where the ambient air is always lower than the temperature required in the electrical enclosure, as they assist the natural convection of the air and help to avoid hot spots. The optional Rainhood’s metal shell provides additional protection from the environment, especially areas exposed to heavy spray.

Pfannenberg’s Filterfan® + Rainhood combination is the market-leading solution for use in extreme environments. The Rainhood’s metal shell provides solid protection against breaking, hides the filter fan from vandalism, provides another barrier against the entrance of water in washdown procedures.

Ideal for energy plants, or battery storage and charging stations where:

- Cool, clean, conditions (-20 to 0 C)

- NEMA Type 12/IP55

- Areas exposed to heavy spray

- Need for small applications

Sample Industry Applications:

- Pitch control cabinets

- Small cabinet

- Gondola shafts

- Rapid charging stations

- Charging pits

Click here to learn more: Filterfans & Sanitary Rainhoods

Related articles: Cooling the control cabinets for a 50 MW photovoltaic plant in the Philippines

PWS Air/Water Heat Exchangers

For the Most Challenging Conditions

PWS Air/Water Heat exchangers are widely deployed to protect variable frequency drives, which are some of the most important pieces of equipment in manufacturing for various processing applications.

PWS Air/Water Heat Exchangers remove a considerable amount of heat while isolating sensitive electronics from a corrosive atmosphere outside of the enclosure.

If a water source is not available on site, facilities can combine PWS Air/Water Heat Exchangers with Pfannenberg Packaged Chillers for an efficient closed cooling solution. Paired with a Chiller, the PWS Air/Water Heat Exchanger provides a total cooling solution that manages process and/or controls enclosure heat gain and effectively removes it from the processing area.

Single source responsibility for the complete system ensures properly matched components that are engineered to work together.

Ideal for energy plants, or battery storage and charging stations where:

- Hot, Dirty and Oily environments (Up to 110 °F)

- NEMA Type 12/3R/4/4x

- Heavy particulate

- Conductive or static electricity

- Flammable, vibrations

- Energy conscious

Sample Industry Applications:

- Wind tower cabinet cooling

- Rapid charging stations

- In-front-of-the-meter applications

Click here to learn more: PWS Air/Water Heat Exchangers

PKS Air/Air Heat Exchangers

For the Harshest Environments

One of the best technologies to use when there is a temperature difference between the internal target temperature and the surrounding temperature (∆T≥10°C) is air to air technology. An air/air heat exchanger removes heat from inside of the enclosure to the cooler environment using the least amount of energy while still providing a closed loop ingress protection.

For example, plants in offshore wind parks are exposed to high humidity – reliable thermal management is provided by air/air heat exchangers which hermetically protect the interiors of electrical enclosures from harsh environmental conditions. Protection against condensate formation is provided by the use of thermostats and hygrostats, which control humidity and temperature, and are combined with heaters or filterfans for electrical enclosures.

Ideal for energy plants, or battery storage and charging stations where:

- Cool, dirty conditions (-13° to 131°F)

- NEMA Type 12/3R/4/4X

- Temperature controlled environment

- Need to reduce heat condensation

- Protection against corrosion and contamination

- Energy conscious

Sample Industry Applications:

- Frequency converters

- Offshore wind parks

Click here to learn more: PKS Air/Air Heat Exchangers

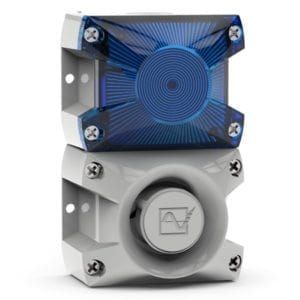

Stack Lights, Signaling and Alarms

For Areas where Employee and Public Safety is Critical

In many energy plants, there is a clear lack of signaling and alarms leading to potential safety issues. In others, signaling confusion occurs when the same signaling is used for different issues.

With robust flashing sounders offering more than eighty tones, our signaling solutions provide widespread coverage through each alarm, significantly reducing the number of signaling devices needed, resulting in an application that not only ensures industrial safety, but is economical as well.

Energy towers and stations often contend with events from the natural environment such as extreme weather, causing exposure for electronics, as well as damage from vibrations. We offer a range of solutions for every aspect of the operation, including;

- PTM 100 Peltier Devices – Vibration resistant for pitch systems. They work reliably (while rotating), even if they are exposed to rainwater, dust or high fluctuations in temperature

- POL 10 Tower aviation Light LED, redundant, 10 cd

- POL 2000R Aviation Light LED, 2000 cd

- PA 100 Sounder for machine start-up

- DS 10 Electronic sounder with VdS, GL approval for fire alert 110 dB

- ABL Flashlight for elevator start-up warning

Ideal for energy plants, or battery storage and charging stations where:

- Machine alarming, indication, or warning required

- Ruggedized, robustness due to humidity

- Flammable materials present

Sample Industry Applications:

- Towers or stations

- Aviation nearby

- Potential for fire

- Elevator notifications needed

- Audible signals when starting up the operation