Cooling Food & Beverage Applications with Pfannenberg’s DTS/DTT Series

Innovative, Efficient, Reliable

Whether in washdown locations or control rooms, the DTS Series key internal electronics are positioned away from potentially moist and/or caustic air in food and beverage applications. The wide condenser fin spacing allows for filterless and maintenance-free operation. The stainless steel units have an epoxy coating on all exposed copper tubing to compliment the electrostatically-coated condensers. The fans are conformal coated, backward curve impellers that have a standard life of 55,000+ hours, providing the longest life and best air flow in their class.

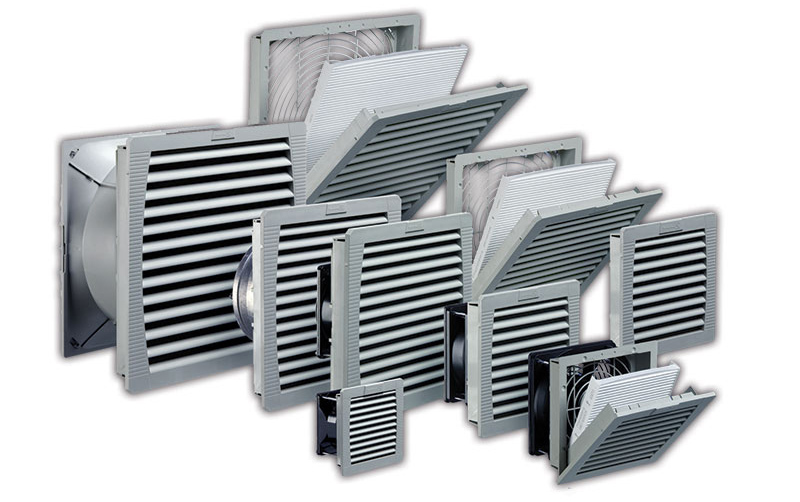

DTS Series Cooling Units

- Active condensate management utilizes a PTC heater which eliminates the need for drain line.

- NEMA Type 4/4X 304 Stainless Steel with #3 polish to repel contaminants in food grade applications and to provide for easy washdown.

- High Temperature models can operate in ambient temperature models can operate in ambient temperatures up to 140° F (60° C), ideal near industrial ovens or baking lines.

- Optional cover to protect fan if used in washdown or in high dust/debris areas.

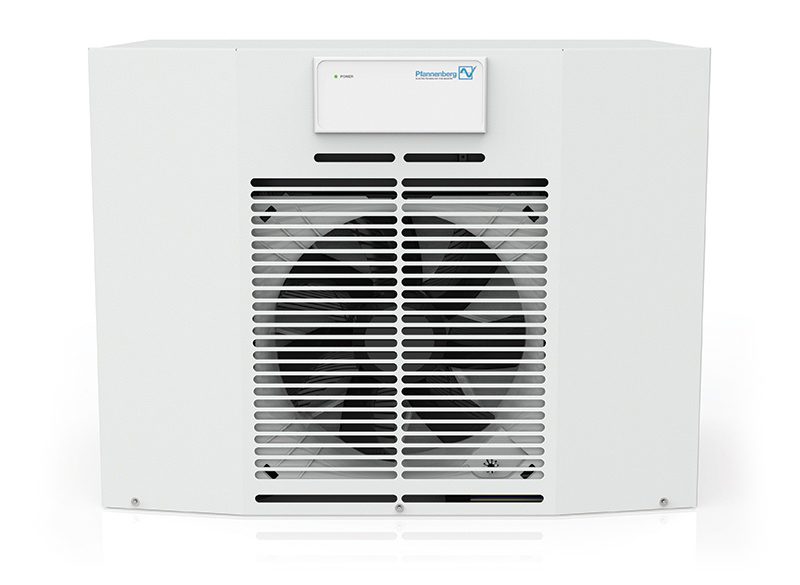

DTT Series Top Mount Cooling Units

- DTT Series Units provide convenient top mount

cooling while eliminating the danger of condensate entering cabinets.

cooling while eliminating the danger of condensate entering cabinets. - Innovative service panel design provides easy to change filters, controls and fuses, decreasing service time and allowing filters to be changed without downtime.

- Product variety: multiple performance levels available.

- Easy mounting: quick release mounting frame and quick mount design.

By keeping electronics in enclosures from overheating, Pfannenberg provides an invaluable service to companies, keeping their machinery and processes consistently operating. By developing and producing products which are designed to save energy and other resources, Pfannenberg operates by their business philosophy – Protecting man, machine and the environment

Topics: Enclosure Cooling, Cooling Units, Thermal Management, North America, Food & Beverage