Pfannenberg Water-Cooled Solutions for Greater Energy Efficiency

Heat is a single common by-product of today’s manufacturing machines that include the advanced automation technology required for both high speed operation and high precision. To keep these processes running, Industrial Cooling is critical. When ambient conditions are at their worst liquid cooling is an ideal efficient solution.

The Challenge…

One of our machine tool customers needed a customized solution adapted to their customer’s environment allowing their industrial electronics to operate at optimal efficiency. Industrial cooling was needed for a grinding machine requiring cooling control accuracy. This is especially important as it significantly influences the grinding tolerance. The machine sands parts to remove all irregularities before sending them off for further assembly (gear manufacturing), the required control accuracy or hysteresis is up to +- 0.1 K in active units and up to +- 0.5 K in passive units.

One of our machine tool customers needed a customized solution adapted to their customer’s environment allowing their industrial electronics to operate at optimal efficiency. Industrial cooling was needed for a grinding machine requiring cooling control accuracy. This is especially important as it significantly influences the grinding tolerance. The machine sands parts to remove all irregularities before sending them off for further assembly (gear manufacturing), the required control accuracy or hysteresis is up to +- 0.1 K in active units and up to +- 0.5 K in passive units.

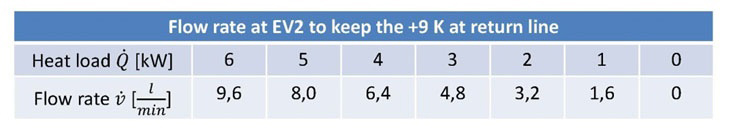

The goal was to cool the machine with available water using a passive enclosure cooling unit at a flow temperature of 22°C. The main requirement for this project was that the water from the return flow (returning to the water ring) had to be at least 9°C warmer to match the customer’s own energy efficiency requirements.

The Solution…

After an analysis of their needs, Pfannenberg’s PWW Water to Water Heat Exchangers appeared to be the best solution. Our water-cooled solutions are designed with durable components to ensure the effectiveness and longevity of the critical cooling process at hand.

We installed our new passive PWW 6000 into our compatible EB 60 WT Chiller housing which is extremely flexible. Passive water cooling makes sense if the flow temperatures are not too low and if a water circuit is available. This solution works reliably at a temperature difference of more than 5°C between the water circuit and the chiller.

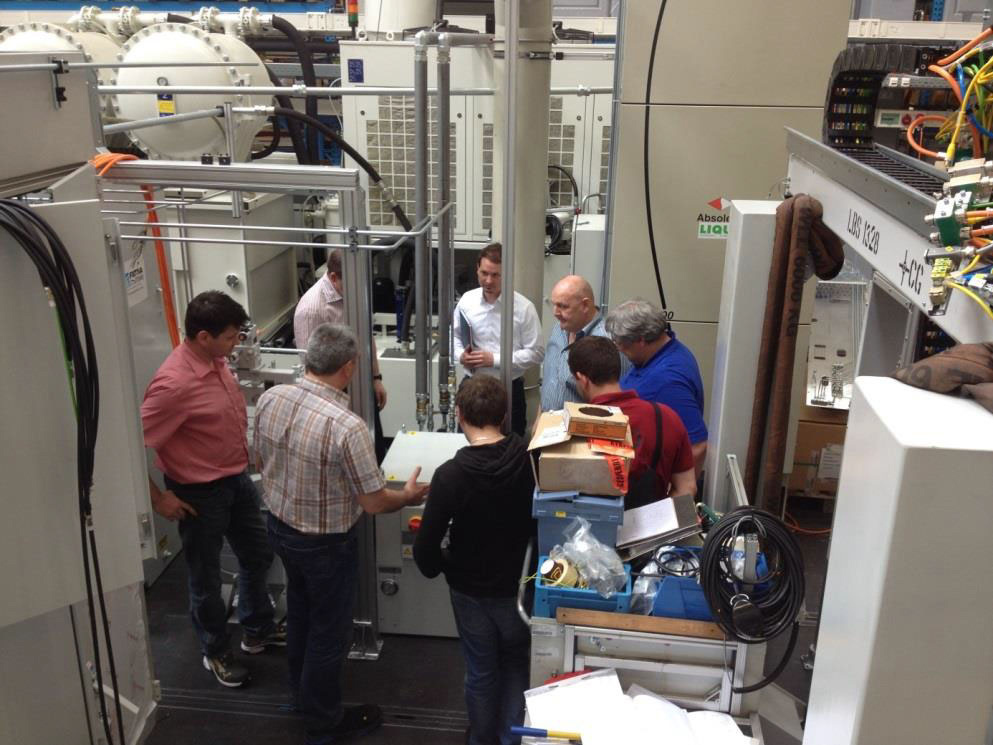

To support this new solution for our customer, Pfannenberg provided 2-days of on-site training bringing “live initial operations” online.

Thanks to the success of this installation, our customer secured 10 more projects using our PWW Water to Water Heat Exchangers with one in China.

Click here to get more information abour our PWW Water to Water Heat Exchangers.

Topics: Enclosure Cooling, Cooling Units, Thermal Management, Water Cooling