DTI 6X2E

X-Series

RECESSED COOLING UNITS

6800-15350 Btu/h

Our DTI 6X2E (NEMA Type 12) series cooling units utilize inverter technology for precise cooling to provide energy efficient cabinet cooling. These cooling units are ideal for mounting on a cabinet door and are partially recessed for space restricted installations. Housing: galvanized sheet steel. Cover: electrostatically powder coated RAL 7035 (light grey)

Features

Inverter Technology

Utilizing inverter technology, each unit covers a wide range of cooling capacity making each unit highly versatile.

Efficient Speed Control

Variable speed compressor adjusts according to the application requirement using less energy compared to fix speed compressor.

Energy Efficiency

Optimized control algorithm leads to significant energy savings for customers.

Connectivity Ready

Comes standard with RS485 interface to enable communication via Modbus RTU protocol.

Precise Cooling

Designed for precision cooling with accuracy of +/-0.1 K (0.2degF).

Multiple Mounting Styles

Available in both recessed mount and side mount to save floor space. One cut out size for models of different capacities.

Easy Installation and Maintenance

Tool-free spring plate design keeps the unit safely in place and allows mounting by 1 person in less than 3 minutes with 55% lower mounting costs. Direct access to the PCB and the fans means 80% shorter repair times.

Thermal Overload Protection

Compressor and fan motors are outfitted with integral temperature switches to shut down the unit in the event of excessive temperature.

Pressure Overload Protection

High pressure cutout switch ensures safety by shutting off the compressor in the event of excessive pressure appearing in the refrigeration circuit.

Closed Loop Design

Designed to isolate the external ambient air from the internally conditioned air eliminating the risk of contaminants entering the cabinet.

Thermal Expansion Valve

Regulates the flow of refrigerant based on thermal demand for efficient performance over the entire operating temperature range.

Efficient Circulation

Large distance between intake and exhaust vents for efficient air circulation and elimination of hot spots.

Maintenance Free, Filterless Design

The wide fin spacing is less susceptible to clogging from dirt buildup which can cause the unit to work harder and hamper efficiency.

External Display

For visual temperature monitoring.

High Airflow Backward Curve Impeller Fan

Provides high airflow in a long lasting, single bearing design. Outperforms typical two-bearing blowers with nearly twice the lifespan.

Hermetically Sealed Compressor

The absence of any refrigerant fill valves eliminates leak paths. Recharging is never needed. 100% cooling capacity efficiency is ensured.

Active Condensate Management

Condensation is a natural byproduct of refrigeration. The heated condensate collection pan boils this off thereby eliminating the need for drain tubes and buckets. To conserve power, this heater only activates when necessary.

Technical Data Overview

| DTI 6X1E | 400/460 V |

|---|---|

| PART NUMBER | 13897832555 |

| FREQUENCY (Hz) | 50/60 |

| POWER CONSUMPTION (W) | 240 - 2020 |

| STARTING CURRENT (@35A/35A) | 4.6 |

| FUSE (max.)** CLASS CC | 10A |

| NOISE LEVEL*** dB(A) | ≤73 |

| WEIGHT lb (kg)(without packaging) | 84 |

| DIMENSIONS | 60.55 in. (1538mm) h x 19.09 in. (485 mm) w x Intrusion Depth 4.72 in. (120 mm) Protrusion Depth 14.65 in. (372 mm) |

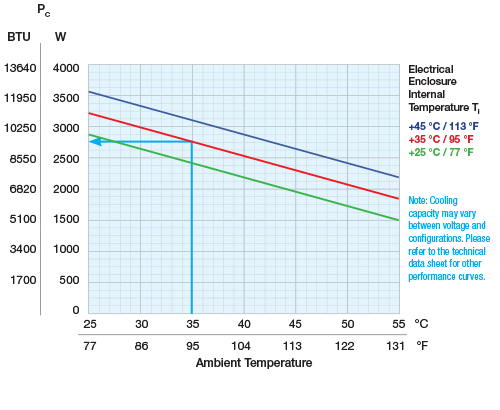

Performance Curve

How to use this chart:

Example: @ 95°F (ambient, X-axis), @ 95°F (internal, diagonal lines)

= 13650 Btu/h cooling capacity (Y-axis)

Additional Data

| AMBIENT TEMPERATURE RANGE | + 59°F … + 131°F / + 15°C … + 55°C | |

| CONTROL RANGE (adjustable) | SC | + 77°F … + 113°F / + 25°C … + 45°C; factory setting + 95°F / + 35°C |

| REFRIGERANT | type | R134a |

| quantity | 1950g | |

| CONDENSATE MANAGEMENT | integrated condensate evaporation system with safety overflow | |

| PROTECTION SYSTEM ACCORDING TO EN 60529 | IP54 towards the electrical enclosure if used as intended by the manufacturer | |

| IP34 towards the surroundings if used as intended by the manufacturer | ||

Subject to technical amendments and misprints.

Latest Posts

Introducing the PROTECT Series: Pfannenberg’s New Benchmark in Industrial SignalingJune 20, 2025 - 9:48 AM

Introducing the PROTECT Series: Pfannenberg’s New Benchmark in Industrial SignalingJune 20, 2025 - 9:48 AM Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM

Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM

Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM