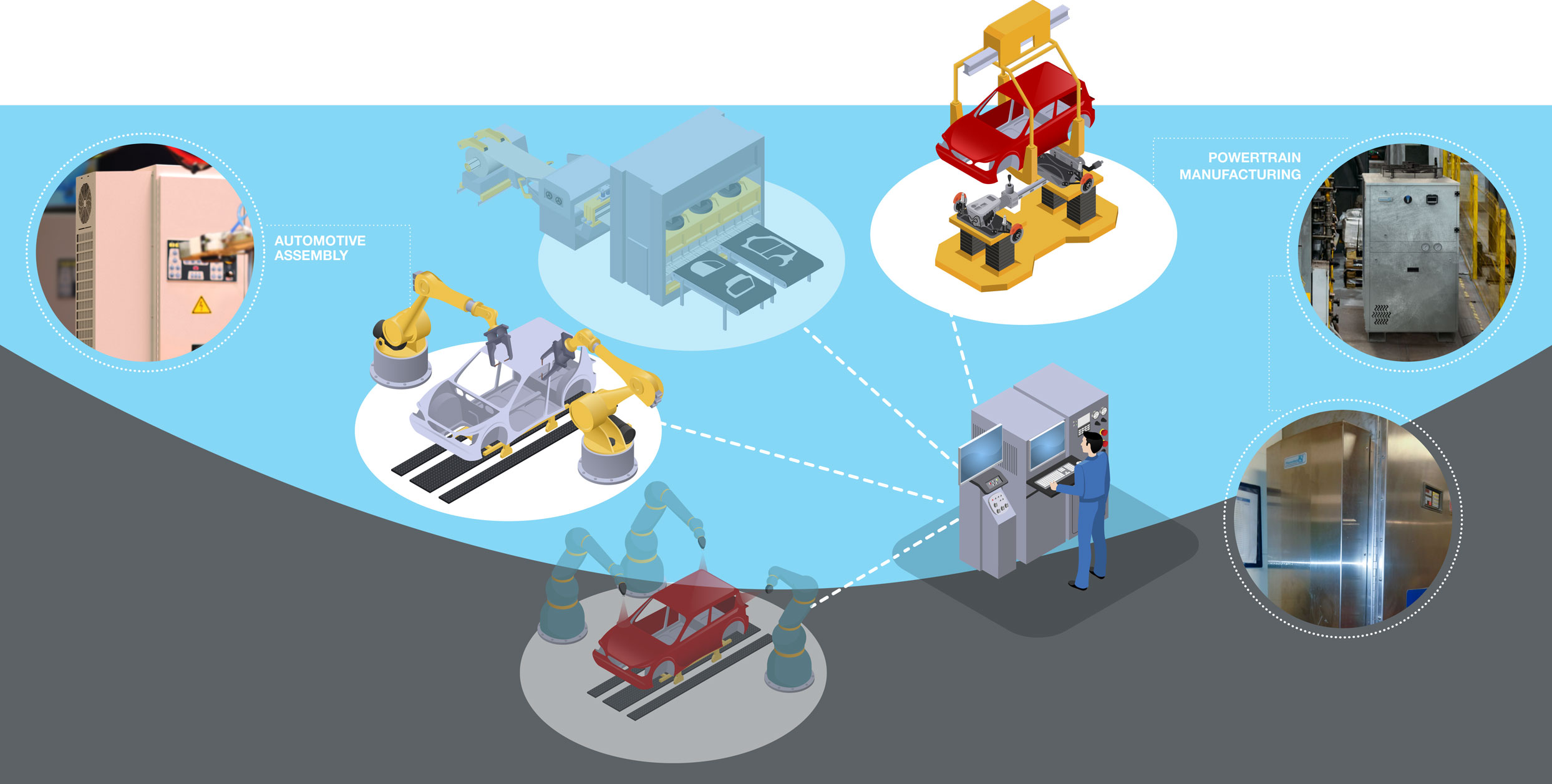

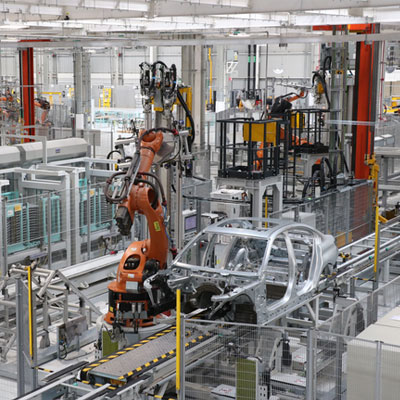

Automotive Assembly/span>

Our space-saving top-mounted DTS Cooling Units are ideally suited for use in vehicle construction and with their patented condensate management they guarantee 100% condensate protection

Powertrain Manufacturing

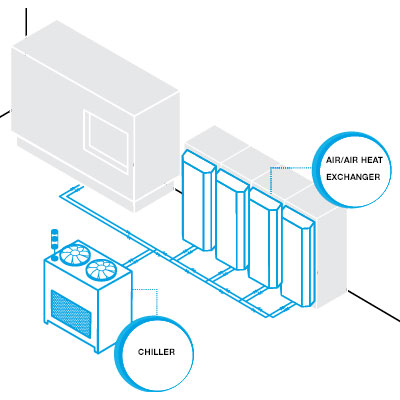

Our chillers are the recommended solution for the reliable cooling of spindles, engines, hydraulic systems and cooling lubricants. In combination with our air/water heat exchangers, they provide perfectly matched system solutions.

POWERTRAIN MANUFACTURING

Systems producing engines, gearboxes, axles or drive shafts are exposed to extreme stress, our air/water heat exchangers are designed for this environment. Whether the ambient conditions involve high temperatures or oily air, we ensure that nothing compromises your production safety or speed. Liquid Cooling provides contaminant-free, cost-effective component cooling without adding heat to the local environment.

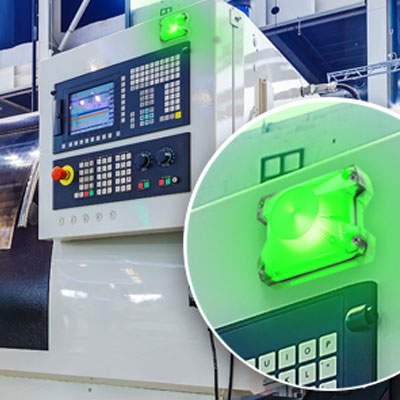

AUTOMOTIVE ASSEMBLY

Wherever the temperature has to be right, we are there for you. Our DTS Cooling Units are highly energy efficient and low maintenance – in fact, filters can be changed without tools in just a few seconds. These devices provide perfect cooling for numerous electronic components in production – for example, when doors or tailgates are formed in the steel press, or when robots carry out delicate painting or assembly jobs.

Products at a Glance

Case Studies & Articles

Pfannenberg’s Liquid Cooling Solutions for Industrial Electronics

Pfannenberg’s Partnership with the BMW Group

PYRA LED: Flexible enough for Any Industrial Application