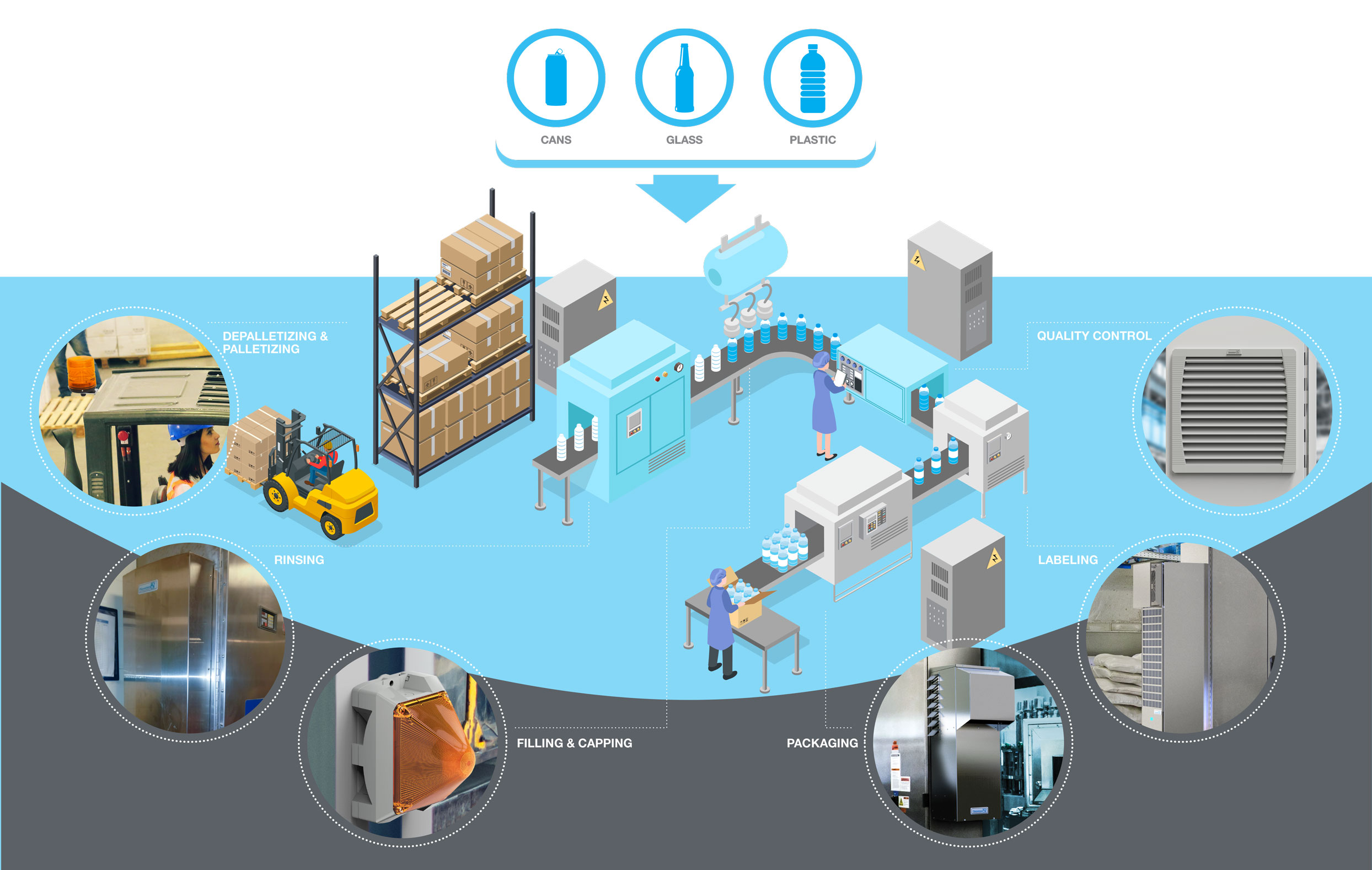

Depalletizing & Palletizing

Consider our signaling solutions for traffic safety when using forklift in your production area. Gas detection alarms are needed in areas where gas leak could occur.

Rinsing & Drying

In hot and moist areas, stainless steel, wash-down PWS Air/Water Heat Exchangers or DTS Cooling Units will keep your rinsing and drying equipment operating perfectly.

Filling & Capping

Where sound levels may exceed 100 dBA, our combined visual and audible alarms are especially effective to protect your personnel in hazardous areas.

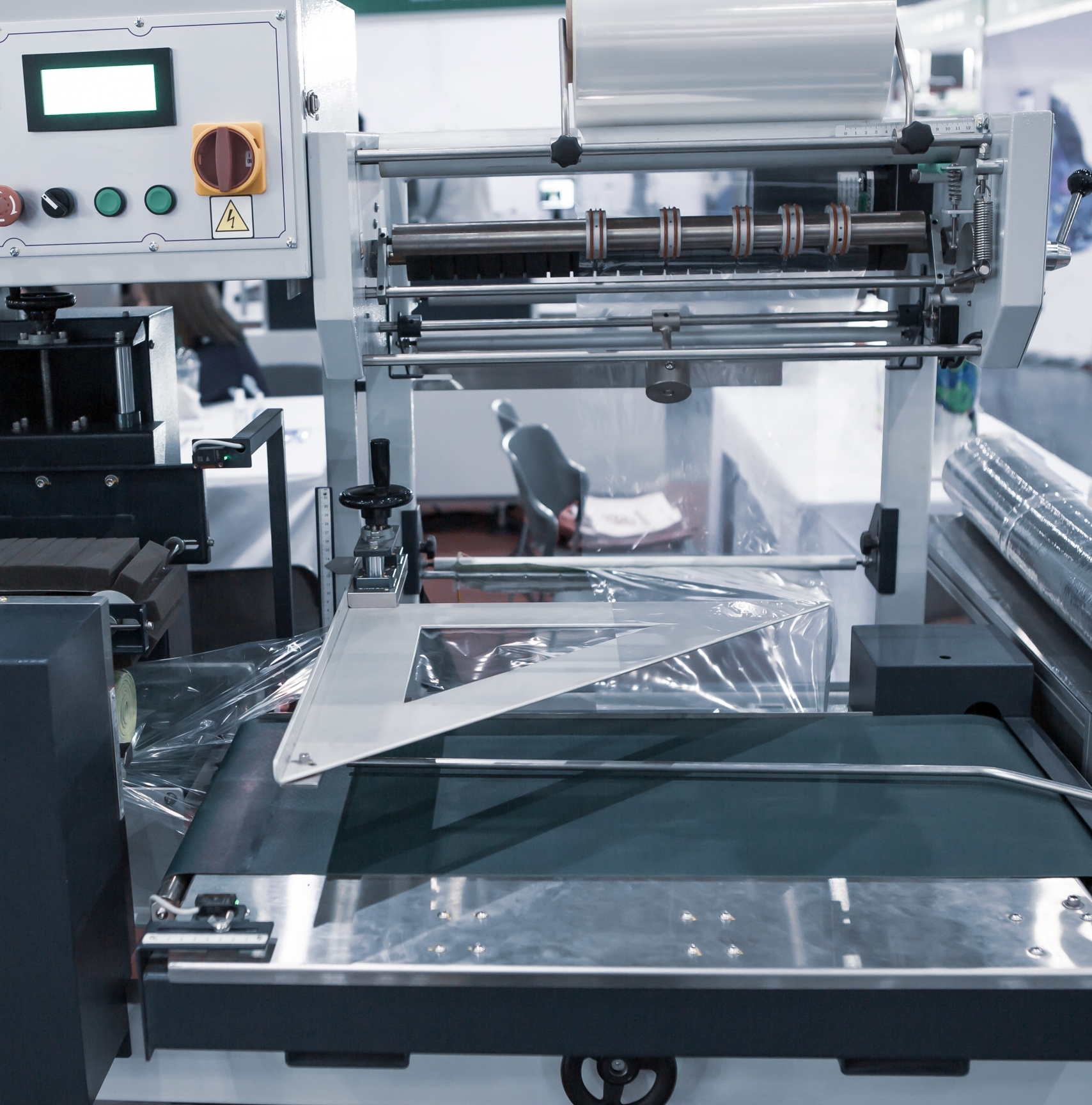

Packaging

Filterfans or air/air heat exchangers are optimal in clean areas with lower ambient temperatures. Where there is a more viscous liquid, look to a DTS Cooling Unit or PKS Air/Water Heat Exchanger.

Labeling

Stainless steel DTS (Side Mount) and DTT (Top Mount) Cooling Units are perfect for labeling areas, as they provide a cold air flow and filterless design.

Quality Control

Pfannenberg Filterfans® and Exhaust Filters provide an IP55 Type 12 protection for X-ray and vision systems.

CANS

Depalletizers, filling and capping machines, high production fillers and pasteurization equipment, all require thermal management to operate effectively. We recommend DTS Air/Water Cooling Units for dirty areas. For cleaner areas in the plant, a Filterfan® or PKS Heat Exhanger can be utilized for energy savings and cost-efficiency.

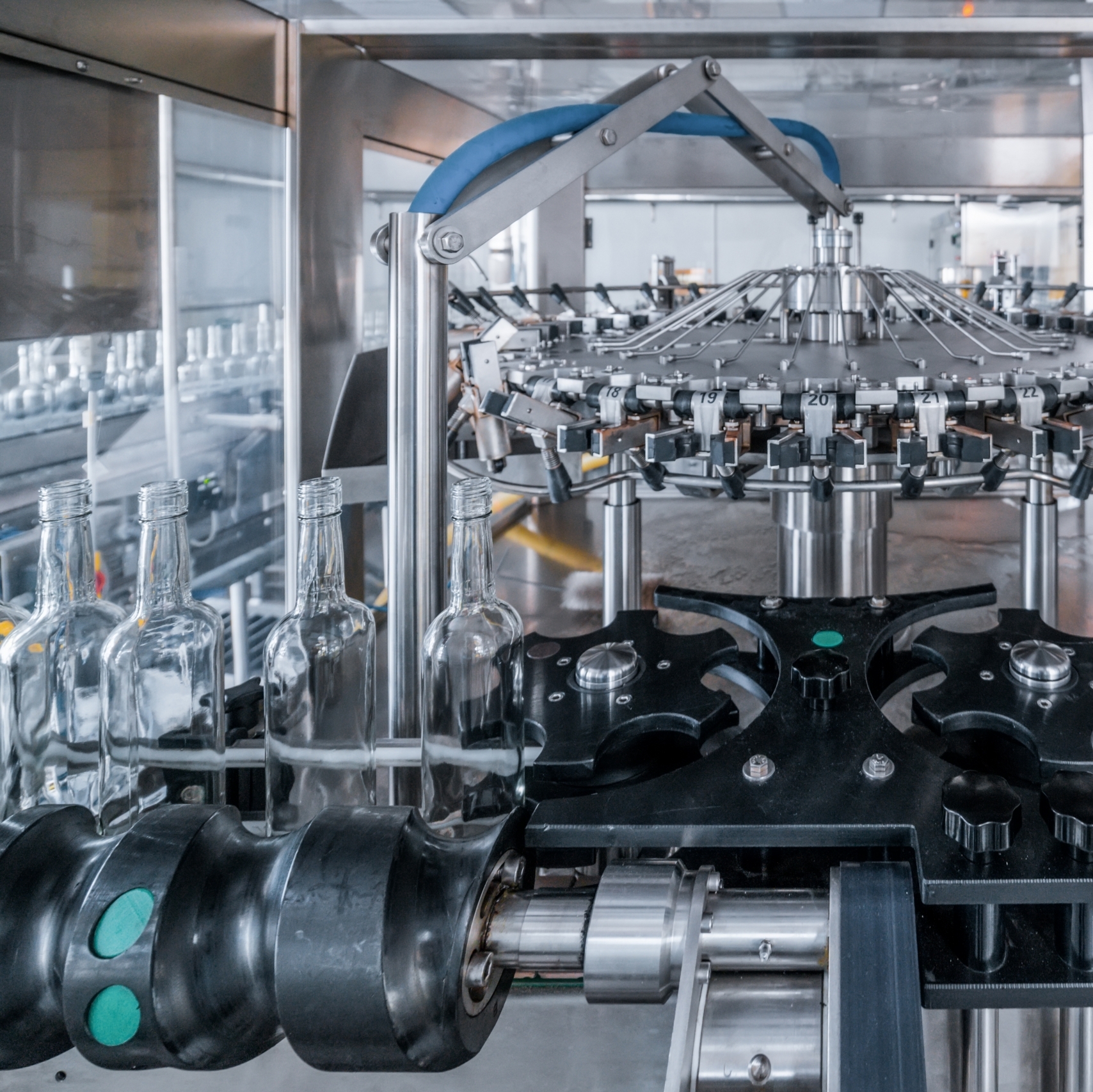

GLASS BOTTLES

The availability of existing water supplies in bottling plants, makes the PWS Air/Water Heat Exchanger a cost-effective and efficient solution for protecting equipment such as flow filters, which are extremely valuable and can handle a range of products from liquids to frozen, hot to cold, and viscous to free flowing.

PLASTIC BOTTLES

DTS Cooling Units, PWS Air/Water Heat Exchangers and/or EB Chillers, are used to protect plastic blower machines, mold blower circuits, air conveyors, filling, capping and labeling, as well as for palletizers and shrink wrappers. And, our BR50 signaling product has been adopted by plastic bottle producers for heavy traffic areas.

DEPALLETIZING & PALLETIZING

Our Nema (Type 12) DTS Cooling Units provide thermal management for palletizer and depalletizers, as well as for production line bulk conveyor systems. Due to the high traffic here, adding a flashing strobe to fork trucks, alarms for gases, and traffic signals to the loading docks, help protect personnel.

RINSING & DRYING

In areas that are hot and moist, such as the bottle and can rinsing and drying areas, we offer stainless steel wash-down DTS Cooling Units, or PWS Air/Water Heat Exchangers if you have water available, to protect your switch cabinets and other enclosure electronics from condensation and/or corrosion.

FILLING & CAPPING

Filling and capping areas need to maintain machine uptime and personnel safety. High-speed movements of equipment and products, along with hard walls and ceilings, lead to sound levels that may exceed 100 dBA. Our signaling devices will help your personnel see/hear the danger and avoid accidents.

QUALITY CONTROL

Automated x-ray and vision systems inspect everything from fill levels to labeling and overall quality, often operating in 95°+ Fahrenheit. Our Filterfans® and Exhaust Filters provide an IP 55, Type 12 system of protection to cool the switch cabinets for automatic inspection systems ensuring these electronics do not overheat bringing QC operations to a halt.

LABELING

High speed labeling requires thermal management for many components. For example, stainless steel DTS Cooling Units are used for switch cabinets of labeling machines with internal brushless circuits, as well as for air knife drying systems where it provides a cold air flow and filterless design, eliminating overheating of the variable drives.

PACKAGING

To lower your energy footprint and save money in cleaner areas with lower ambient temperatures, consider Filterfans or air/air heat exchangers. A DTS Cooling Unit or PWS Air/Water Heat Exchanger, provide a more hardened solution where there is higher heat, and equipment such as fillers processing a more viscous liquid.

Products at a Glance

Case Studies & Articles

Enclosure Cooling Units Help Support Bottling Inspection