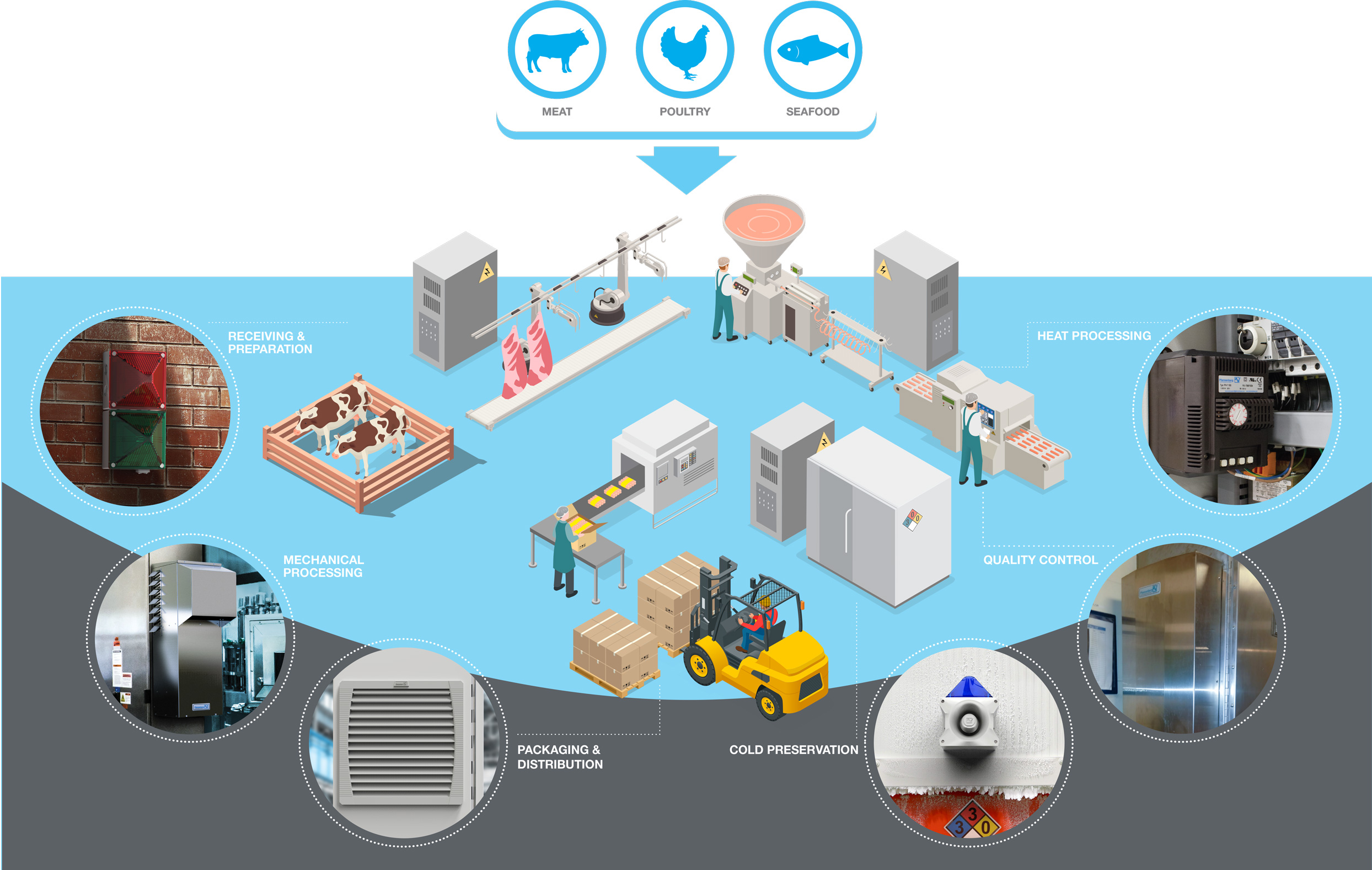

Receiving and Preparation Area

In preparation areas where animals are being received and transported between holding pens, consider PA X 1-05 signaling alarms for fork lifts and other vehicle traffic.

Mechanical Processing

Cold rooms may require the PKS Air/Air Heat Exchanger, which offers a simplistic closed loop design that survives daily washdowns with caustic chemicals.

Heat Processing

Where warm or hot conditions are present sensitive electronics benefit from a DTS Cooling Unit.

Food Safety Inspection

The PWS Air/Water Heat Exchanger with packaged chiller is suitable to ensure proper operation of x-ray and metal detection equipment.

Cold Preservation

Applications that require refrigeration benefit from our PA X 10-10 gas detection alarms to protect personnel in the event of an ammonia or other chemical leak.

Packaging and Distribution

From Filterfans® to PKS Air/Air Heat Exchangers we provide a range of thermal management to protect your shrink wrappers and labeling equipment.

RECEIVING AND PREPARATION

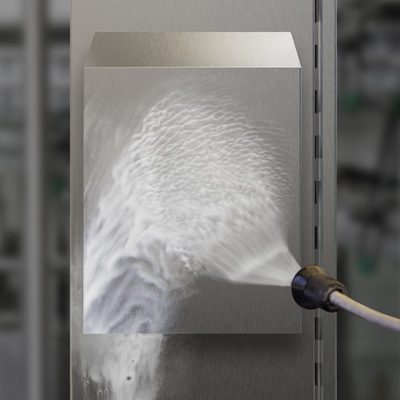

Where livestock is being transported, consider PA X 1-05 alarms for vehicle traffic. Spray down equipment and conveyors require the wash-down PWS Air/Water Heat Exchanger, as they are constantly cleaned to remove bacteria.

MECHANICAL PROCESSING

Cutting, portioning, and tumbling machines are often located in colder ambient temperature, such as a (55 F) freezer room. The PKS Air/Air Heat Exchanger, offers a simplistic design that survives daily washdowns with caustic chemicals.

HEAT PROCESSING

Where warm or hot conditions are present (85-110 F), oven, smokers, and other heat sensitive electronics benefit from a DTS Cooling Unit. Thermostats and Heaters may also be needed for condensation control.

FOOD SAFETY INSPECTION

The PWS Air/Water Heat Exchanger with packaged chiller ensures proper operation of Xray and metal detection equipment in warmer ambient temperatures, reducing the likelihood of food contamination, and keeps plants compliant with the Food Safety Act.

COLD PRESERVATION

Applications that require refrigeration, such as cold rooms, freezers, and flash freezers, benefit from our PA X 10-10 gas detection alarms to protect personnel in the event of an ammonia or other chemical leak. Gas Detection signals must be different from fire alarms to avoid confusions.

PACKAGING AND DISTRIBUTION

From Filterfans® to PKS Air/Air Heat Exchangers we provide a range of solutions to protect shrink wrappers and labeling equipment. In distribution, the Quadro LED TL traffic light, can warn of capacity overload, wind, crane movement and load rotation.

Products at a Glance

Case Studies & Articles

Avoid Overheating in Vacuum Turkey Packaging

The Future of F&B Preservation Using Chillers

Pfannenberg Assist in Making an American Summer Treat

Pfannenberg’s FDA Compatible Nema Type 3R/4/4X Rainhoods