Thermal Management Protection Solutions For Edge Computing Environments

By Jonathan LaPorta, Pfannenberg USA

Select the right option to ensure continuous operation of senstive electronics

Edge computing – placing application logic as close to the source of data as possible – reduces latency, optimizes bandwidth usage, and minimizes costs, all while increasing visibility and control, speeding up processing, and enhancing user experience. The challenge is that enclosures used to protect distributed computer equipment from the immediate environment oftentrap heat generated by the electronics. Read on to learn about thermal protection solutions that ensure continuous operation of sensitive electronics in edge computing environments.

Benefits of Edge Computing Fuels Explosive Growth

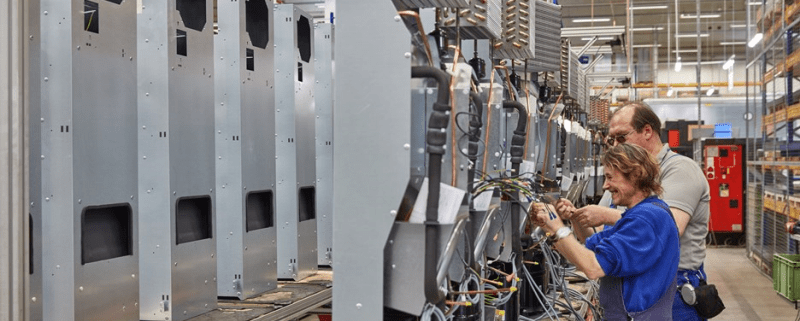

The adoption of edge computing is accelerating for mission-critical computer components in factories, warehouses, retail stores, hospitals, and college campuses – and indeed in most other sectors. The explosive growth is fueled by megatrends like digitization, the internet of things (IoT), and automation.

Key examples include high-definition video cameras that generate masses of data; machine vision systems used in manufacturing to perform imaging-based automatic inspections; hospitals, which have to store and process medical sensor data and digital health records; and warehouses and retail stores running inventory and point-of-sale systems.

All that data needs to be processed somewhere, and it is usually much faster and more efficient to do it close to the edge where people and things produce and use that information. Keeping and processing data at the edge can also enhance reliability, security, and privacy by minimizing the transmission of sensitive information and exposure to network failures and malicious attacks.

Protecting Distributed Components is Critical

In edge computing environments, computing equipment is located outside of a climate-controlled data center. Servers and networking gear are often placed in crowded factory floor spaces, up in warehouse rafters, or in closets. They may be located in inhospitable environments, with high ambient temperatures, or dust- and oil-filled air. That is why distributed computer equipment is typically placed in enclosures for protection. Unfortunately, the enclosures themselves trap heat generated by the electronics, so they require protection from overheating.

Simple, Proven Cooling Solution

A variety of cooling methods have proven effective for thermal management of electrical enclosures. Filter fans are an economical solution when the ambient temperature is always lower than the temperature required by the computer components inside. One example is Pfannenberg’s new Datawind Filterfan®, which has a temperature indicator and is mounted externally to the enclosure to enable full use of all racks within the bays.

More Challenging Cooling Applications

Some applications require enclosures specially designed for challenging environments, from weather and impact-resistant outdoor enclosures to tightly sealed stainless steel enclosures for food production facilities that must withstand high pressure cleaning.

A closed loop cooling system is required when the interior air of the electrical enclosure must be protected from the exterior environment. Air to air technology is one of the more energy efficient technologies to use when there is a temperature difference between the internal target temperature and the surrounding temperature (∆T≥10°C). Pfannenberg’s Kinetic System™ (PKS) Series Air to Air Heat Exchangers remove heat from inside of the enclosure to the cooler environment using the least amount of energy while still providing a closed loop ingress protection.

If the electronics generate a high heat load and/or the ambient air is too warm to provide adequate cooling, an active cooling system such as the Pfannenberg DTS Series of side mounted cooling units may be required. These air conditioning systems utilize a compressor for cooling in a closed loop design that isolates the interior of the enclosure from the exterior environment.

Ideal for extremely demanding industrial and outdoor applications, Pfannenberg’s DTS units provide NEMA 4 level of protection from washdown conditions and caustic air and can operate in ambient temperatures up to 140° F (60° C).

By implementing the optimal cooling solution for distributed components operators can take advantage of edge computing’s many benefits while protecting mission critical IT infrastructure from overheating.