Pfannenberg concludes exclusive agreement on thermal management solutions with the BMW Group

Thermal management specialist Pfannenberg has concluded an exclusive agreement with the BMW Group on thermal management solutions for the production plants at all sites worldwide.

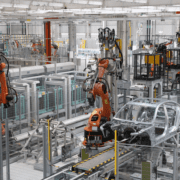

Picture Source: BMW AG

Pfannenberg’s energy-efficient, low-maintenance and long-lasting thermal management solutions as well as our global presence were decisive in the conclusion of this partnership. Depending on site, environment and application, we offer a wide range of thermal management solutions – from filterfans® and air/air heat exchangers to air/water heat exchangers and cooling units.

The perfect cooling solution for any requirement

Whether painting or assembly work, manufacturing in the automotive industry uses many different processes at the same time and production efficiency is a top priority. Cooling requirements vary depending on the application, and a precise analysis of the needs is necessary to define the appropriate performance. Otherwise, an oversized system can lead to higher energy consumption. In this area, Pfannenberg offers the right thermal management solution for every cooling requirement and ensures an energy-efficient and smooth production sequence. In particular, Pfannenberg’s ECool series cooling units stand out for their high performance, intelligent control and exceptionally easy-to-maintain design.

Translated with www.DeepL.com/Translator (free version)

“We are very pleased about this cooperation and look forward to the coming years as a partner of the BMW Group. Thanks to the outstanding cooperation of the technical team, the customer service and our account managers, we can offer the BMW Group a convincing all-round package” says Jan Lautenschläger, Germany Sales Director at Pfannenberg. “In the production area, an energy-efficient cooling concept is becoming increasingly important and here in particular regarding the CO² emissions along the production chain. Major customers such as BMW are demanding a respective company-wide solution with a sustainable concept for the future. Here, the focus is clearly on energy efficiency and perceivable quality.”

Convincing energy efficiency and ease of maintenance

BMW group’s main requirements were focused on energy efficiency and maintenance needs. Thanks to the installation of test Cooling Units, Pfannenberg convinced in particular with the εCOOL series. A realistic energy consumption analysis facilitated the simulation of the expected energy consumption in various production sites. This analysis showed that due to low ambient temperatures, the real environment will often not require the unit to run at full power. This is where the Pfannenberg’s intelligent energy-saving mode comes into play, with the “cooling mode” being triggered when the required cabinet temperature is exceeded. In addition, the standardized installation dimensions and housing cutouts allow easy replacement of cooling units and quick adaptation to changing environmental conditions and applications.