Download Pfannenberg’s NEW 2016 Thermal Management Catalog!

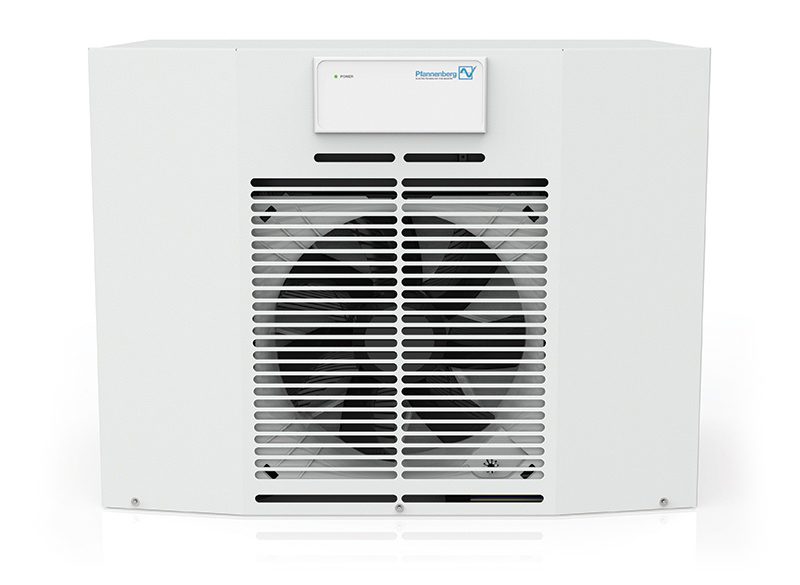

We are excited to announce the release of our NEW NORTH AMERICAN CATALOG. In this catalog we take a Solutions First approach to helping you understand how to choose the best Thermal Management products for your applications.

> New sections for Engineered Solutions and Industry Group Specific Solutions.

> Shared expertise to find the best solution for any type of application and environment.

> Easily determine the correct thermal management products for your application and environment.

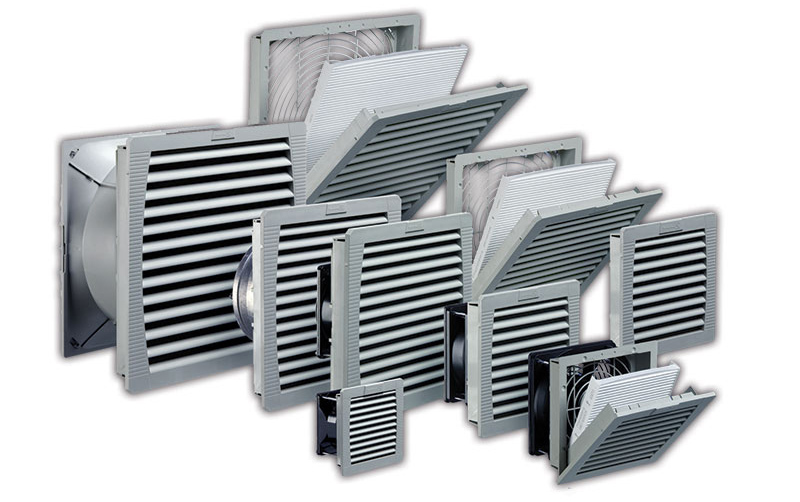

> New high resolution detailed product pictures with cut-aways.

Pfannenberg, Inc. is a global manufacturer of thermal management, water cooling solutions and signaling technology. For more than 60 years, our enclosure cooling products have been helping some of the largest companies worldwide stay cool and safe, protecting and keeping electronic equipment running to avoid costly downtime.

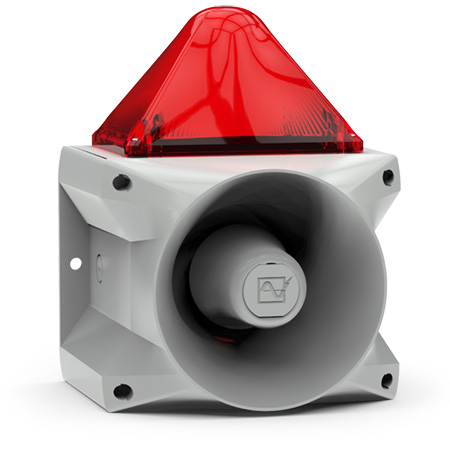

In addition to our thermal management products we also manufacture visual and audible signaling devices for security, industrial fire, building, industrial process, disaster warning, hazardous areas, light art and illumination. Our business philosophy – Protecting man, machine and the environment.

To learn more about how we can help you, contact us today! We have a wide range of expertise to share with you.

Topics: Enclosure Cooling, Thermal Management, North America

Pfannenberg industrial alarms with visual and audible notifications come with a standard 10-Year Warranty, guaranteed to protect man, machine and the environment.

Pfannenberg industrial alarms with visual and audible notifications come with a standard 10-Year Warranty, guaranteed to protect man, machine and the environment.

cooling while eliminating the danger of condensate entering cabinets.

cooling while eliminating the danger of condensate entering cabinets.