NEMA® Type Rating- How Thermal Management Products Play the Role

NEMA® ratings define in which environment an electrical enclosure can be used; the enclosures are rated in the NEMA® Type Rating System according to their use and corresponding necessary environmental protections. Components installed on the enclosure, such as the Thermal Management system, have to pass the stringent requirements of the NEMA® rating in order to be suitable for that enclosure. This blog will speak about the different environments for thermal management technology, and necessary considerations for thermal management solutions to be included into different NEMA rated enclosures.

Open vs Closed Loop

First, separate from NEMA® Type ratings is the determination of whether to use an open or closed loop thermal management system.

Open loop systems use, for example, a Filterfan® to move the hot air from inside the enclosure to the outside environment. The Filterfan® draws in cool ambient air and pushes out warm enclosure air. The filtering capability of the thermal management system is important in open loop environments because the air goes directly into the enclosure, so dust and other particulates must be filtered out.

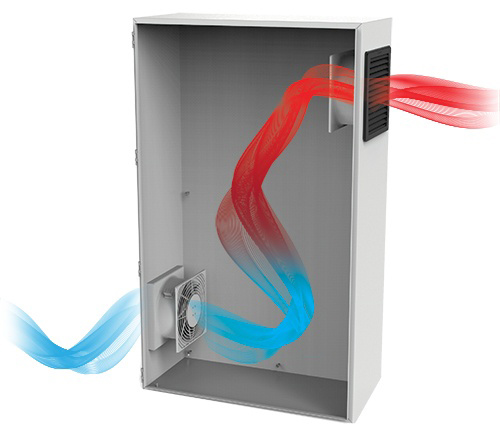

Closed loop systems, in contrast, have two different air circulation loops: one inside the enclosure and one outside, using a condenser coil to cool. The closed loop design protects inside air from outside air, making filtration unnecessary, but the seal between the unit and the enclosure is important for closed loop systems.

Application setting

Indoor Environment

Regardless of application settings, closed or open loop systems may be used. Indoor settings, usually rated to NEMA/UL Type 12, can use Filterfans® with pleated filters as their open loop thermal management systems. The filter itself could be coated with a hydrophobic material to repel water, and would have an IP 54 or 55 rating depending on the presence of that coating. The whole filterfan® system, though, would be NEMA Type rated to 12. Closed loop cooling units in such an application setting would rely on a gasketed seal between the unit and the enclosure.

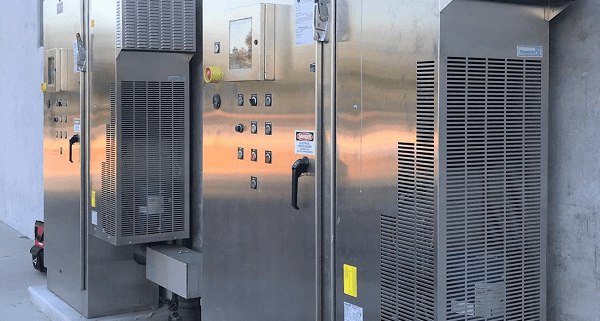

Outdoor Environment

Outdoor settings, usually NEMA/UL rated Type 3R or 4, also can use either closed or open loop systems. In an open loop, the filter blocks dust, while the outer grate, sometimes paired with a rainhood, can block water, wind, and vandalism. The rainhood provides additional protection in these and in closed loop systems; closed loop systems might also use a compressor sump heater forprotection against cold.

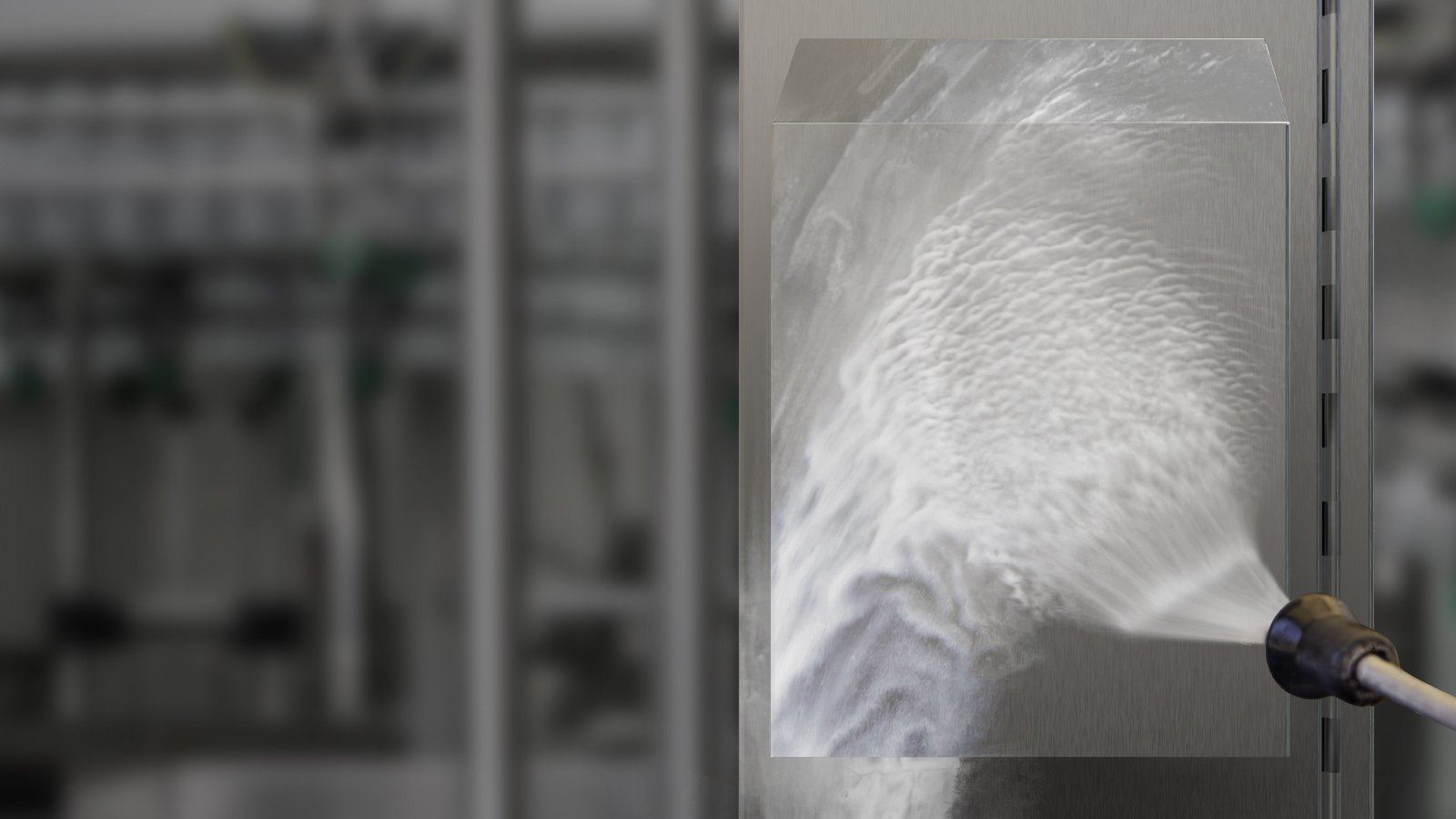

Washdown Environment

Washdown settings, NEMA Type 4/4X rated, require a Filterfans® and rainhood or air conditioning unit and rainhood. What’s more, the rainhood should be designed with a direct spray barrier on the bottom of the rainhood. An air conditioning unit in this type of environment should have a stainless steel cover and rainhood for protection against both corrosion and water ingress. Condenser coils should be corrosion resistant in 4/4X air conditioning applications to reduce corrosion risk.

Hygienic applications

Finally, though not directly related to any particular NEMA Type rating, hygienic applications will have their own specific requirements for thermal management systems on electrical enclosures. These requirements are usually at least as stringent as the washdown environments described above.