Filterfan 4.0 New Video

Trust in the Original

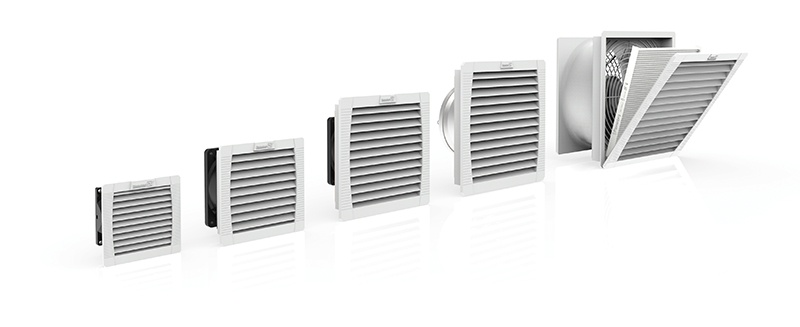

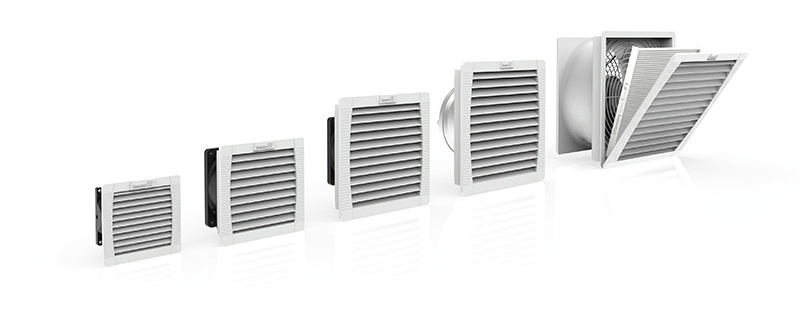

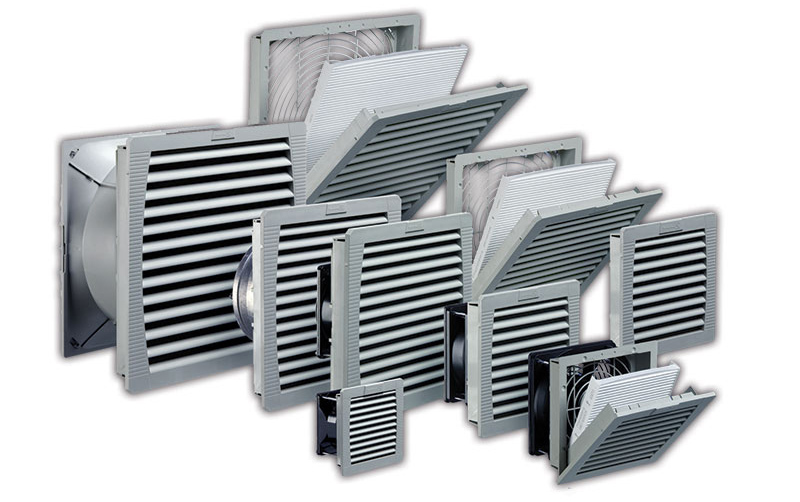

Otto Pfannenberg’s invention of the Filterfan® in 1958 was a milestone in the area of industrial thermal management. From generation to generation, our world-class engineers have been working on the continuous technological development of Pfannenberg Filterfan® products. Numerous improvements are continuously made including several breakthroughs, so valuable that they required international patents. All in all our Filterfans 4.0™ contain 11 field-proven patented features!

Discover below our New Video presenting the great features of our Filterfans 4.0™ line: quick and easy to install, to maintain or to replace and still no tools are required!

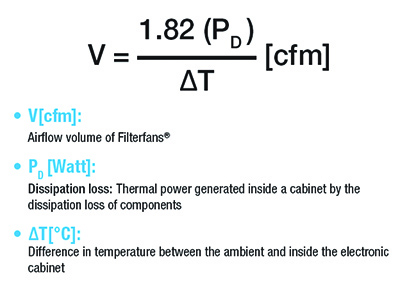

Important for the use of Filterfans®:

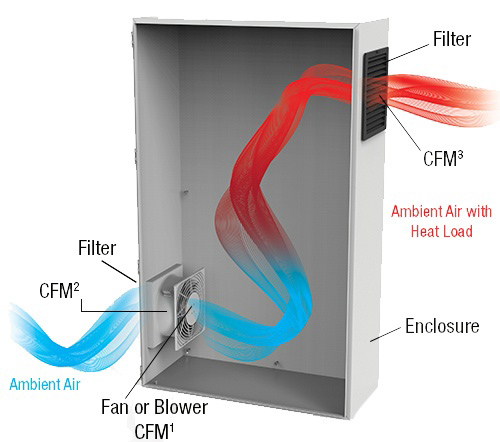

- Use Filterfans® to force the surrounding air into the electrical enclosure, so that a slight overpressure builds up inside the enclosure.

- The surrounding air enters the electrical cabinet exclusively via the Filterfans®, which ensures that it is filtered.

- Install the Filterfans® in the lower third of the electrical enclosure and the exhaust filter as close to the top as possible. This assists the natural convection of the air and avoids hot spots within the enclosure.

Is your enclosure located in a wash-down area? Then Pfannenberg’s Rainhoods are your to-go choice! Their direct spray barrier and high air-flow baffle allow for superior protection from overspray entering the cabinet while minimizing airflow loss, more info here!