Pfannenberg Signaling Expert to Speak About Crane Safety at AIST Crane Symposium

Pfannenberg, Inc., a leading global manufacturer of thermal management and signaling technologies, announces that Audible & Visual Signaling Product Specialist Jake Vernon will present on the topic of Crane Safety at the 26th AIST Crane Symposium, to be held June 2-4, 2019, at the Seelbach Hilton, in Louisville, Kentucky.

Mr. Vernon’s speech will focus on signaling confusion in loud steel making environments. Mr. Vernon will provide an introduction on the science of sound and how it travels, including the concepts of frequency and amplitude, as well as an analysis of the steel making sound environment and crane safety topic.

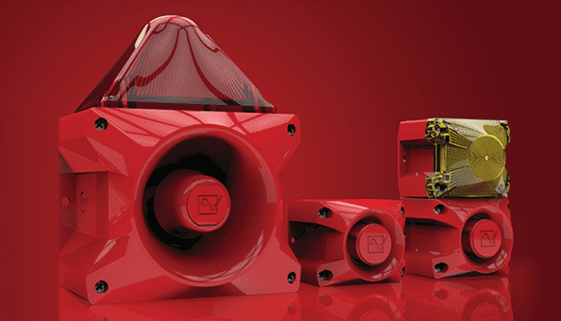

He will then discuss ways to make signaling safer for personnel and machines, including use of such products as Pfannenberg PATROL®Series and PYRA® Series Flashing Light Sounders.

PATROL Series Flashing Sounders offer 80 pre-programmed alarm tones with 4 stages for distinctive signaling of specific events, such as conveyor start-up/stop, material jam, machine fault, and gas detection. Higher frequency tones prove safer for steel making, while other audible and visual signaling cues may lead to confusion.

PATROL Series Flashing Sounders offer 80 pre-programmed alarm tones with 4 stages for distinctive signaling of specific events, such as conveyor start-up/stop, material jam, machine fault, and gas detection. Higher frequency tones prove safer for steel making, while other audible and visual signaling cues may lead to confusion.

Rugged PYRA Flashing Light Sounders emit extremely bright alarm flashes of up to 15 Joules. Selectable flash frequency, optional control input flash activation, and separate visual and acoustic signal controls make them a good choice for crane safety in loud steel making environments.

About Pfannenberg

Established in 1954 by Otto Pfannenberg in Hamburg Germany, Pfannenberg is recognized as a leading global manufacturer of thermal management technologies within the Electro-technology Industry. In 1958 we invented the Filterfan®, which continues to be recognized worldwide as a leading product to help manage the temperature in electrical enclosures. Our business philosophy: Protecting Man, Machine and the Environment.