Wireless and LED Technology Offers Flexibility and Reliability

By Jake Vernon, Pfannenberg USA, Inc.

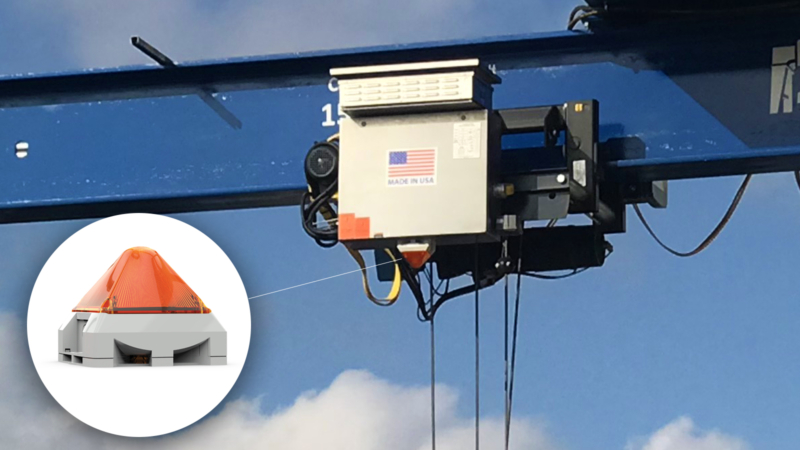

Emergency notification systems are critical to plant safety, but can be unwieldy and costly. A number of variables impact the implementation of an effective signaling system including the size of the facility, the types of alerts needed, budget constraints, and the type of work the facility conducts. To meet these variables, the signaling industry trends have moved toward the use of more flexible and reliable signaling solutions developed around cost-effective wireless and LED technologies.

Signaling Industry Trends: Emerging Technologies

Wireless technologies

Wireless signaling capabilities have greatly expanded and consequently, the emergency alert industry has seen an increased interest in integrating wireless technologies into emergency alert systems. Moving signaling systems to wireless channels, such as Wi-Fi or radio, poses two significant benefits to customers. First, the cost savings for a wireless system can be tremendous. In a large food processing facility, for example, the cost of wiring can far exceed the price of the signaling devices. Electrician fees can make up 50-75% of installation costs for a wire-run signaling system.

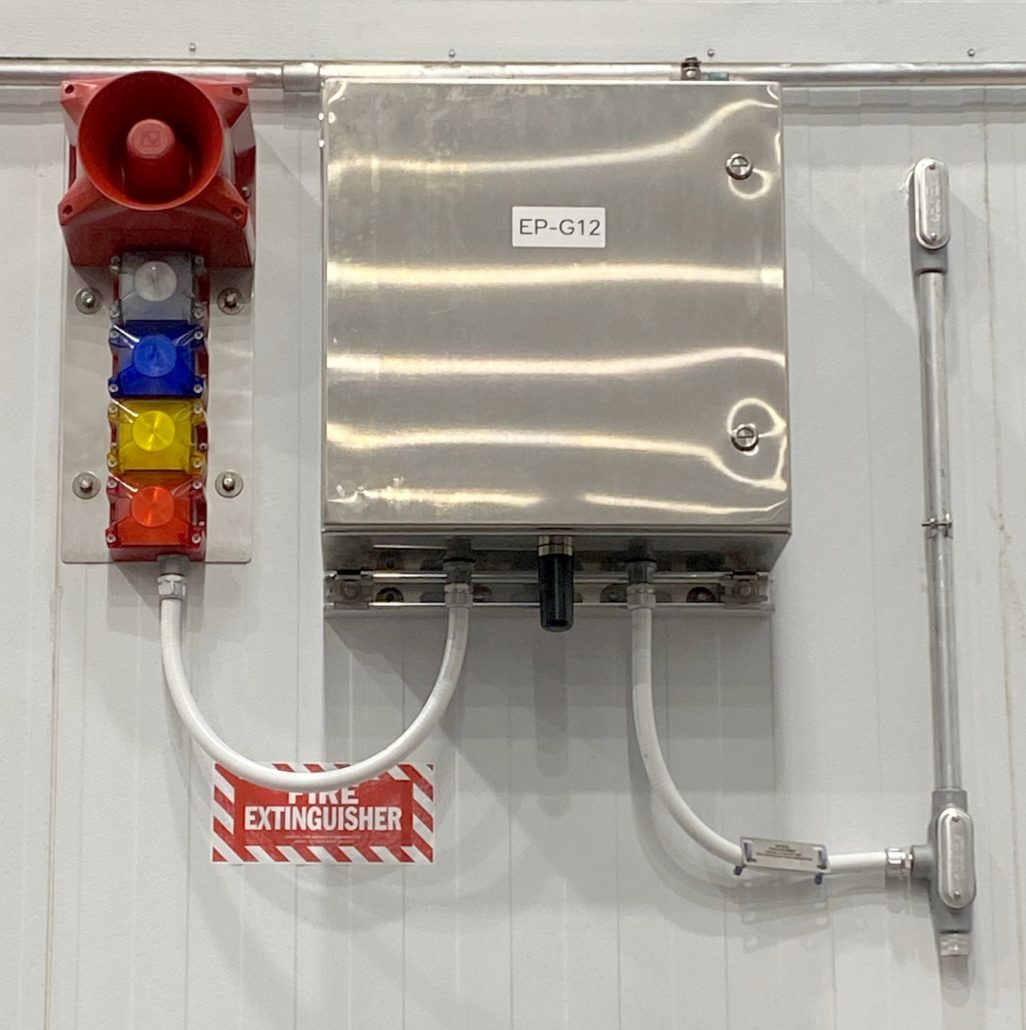

Along with Wi-Fi network systems being quicker and easier to install compared to wired systems, they can also be easily expanded or adapted to accommodate new notification devices. This flexibility makes them ideal for situations where scalability is a concern. They also enable the potential for all emergency notifications (gas leak, fire alarm, active shooter alerts) to be centralized in one system, where they can be dispersed to necessary stakeholders. Wi-Fi systems can be easily integrated with other communication and notification systems, such as smartphone apps or central control centers. This enhances the effectiveness of emergency notifications by reaching a wider, or more targeted, audience.

Centralizing emergency alerts allows companies to aggregate their emergency alert data. This data provides tangible safety metrics for tracking against company KPIs. Its tangibility also makes this data actionable. Ultimately, bolstering employee safety and keeping additional employee costs down.

LED technologies growing in popularity

LED technologies growing in popularity

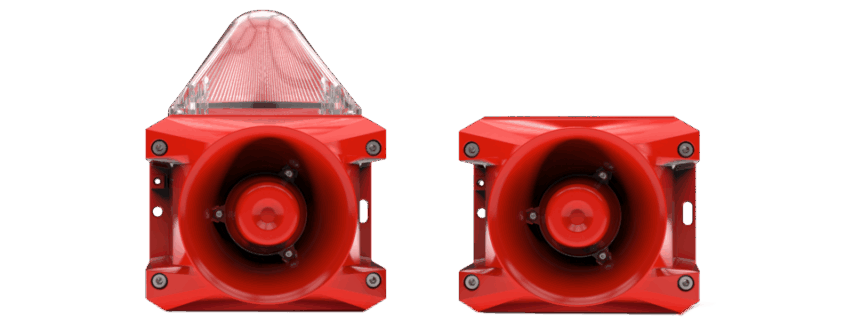

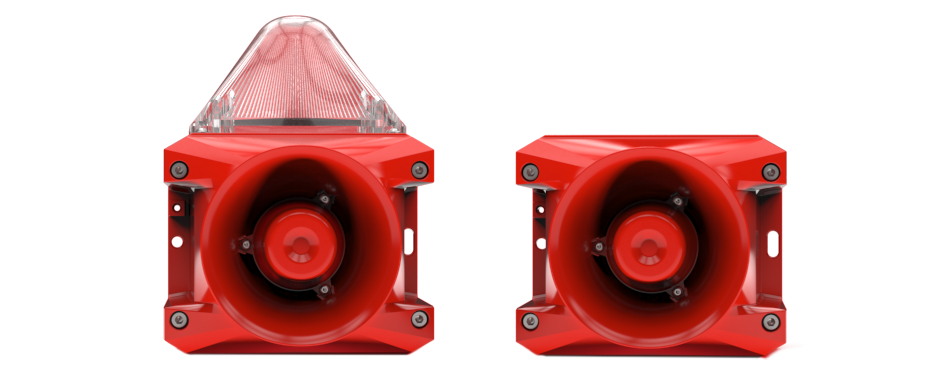

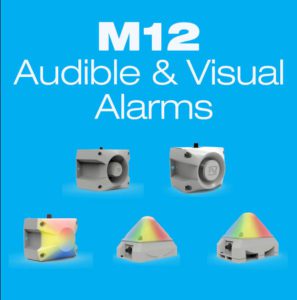

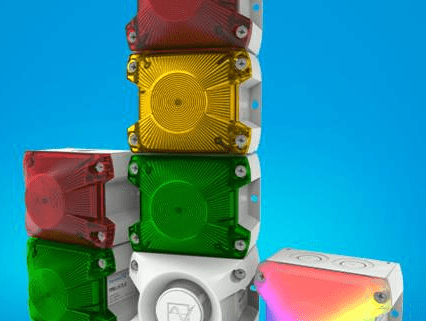

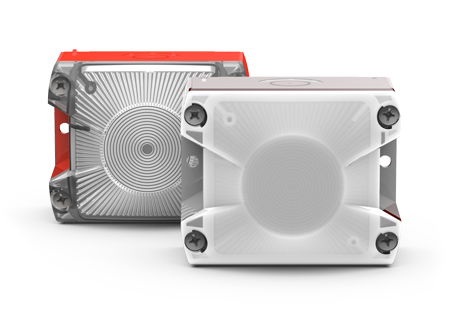

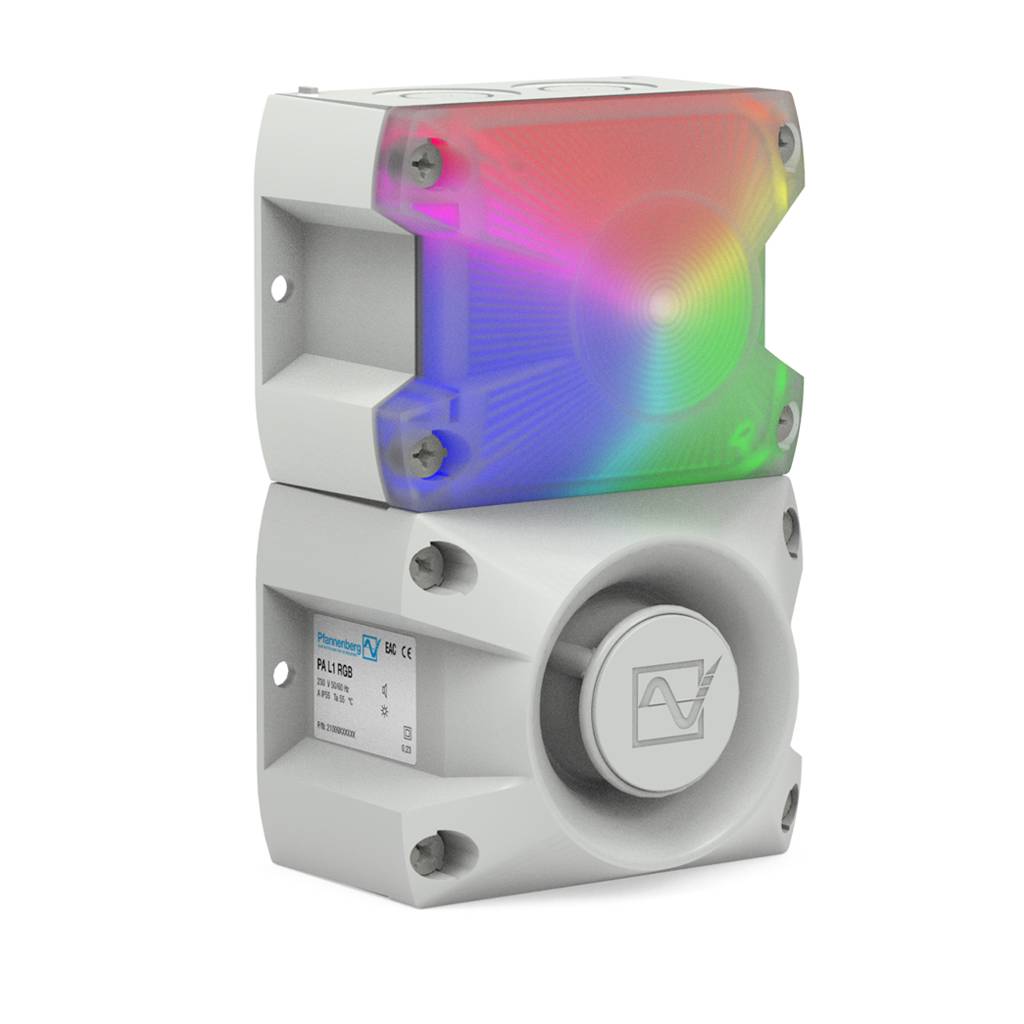

Equipping emergency alert systems with LED lights is growing in popularity as well. LEDs are extremely versatile and offer unparalleled reliability. LED offers a long use life, with over 50,000 hours of on-time. Plus, they offer variability in presentation. LED lights can stay on continuously, blink, flash, and dim—all great options for differentiating between emergency notification signals. LEDs are also available in various colors, allowing for flexibility in designing emergency notification systems. Different colors can convey specific messages or indicate different types of emergencies. For example, red lights might signal a fire emergency, while blue lights could indicate a medical emergency.

LED lights are highly energy-efficient, consuming significantly less power than traditional incandescent or fluorescent lights. This longevity is crucial for emergency notification systems, which may need to operate for extended periods of time during power outages or emergencies. LED lights can also be powered by batteries or backup generators.

Compared to incandescent lights, LED lights produce very little heat. This reduces the risk of fire hazards and allows LEDs to be used in various applications and even enclosed spaces. LED lights can easily be integrated with modern control systems, enabling automated or remote activation as part of a comprehensive emergency notification system.

Overall, the energy efficiency, reliability, and flexibility of LED lights make them an excellent choice for emergency notification systems. However, while LED is growing in popularity, Xenon still offers the highest-impact flash. In high intensity scenarios, a blinking LED might not be the best suited for catching employee attention. That’s a situation where a Xenon-powered strobe might be more effective.

Consistent Considerations

Outdoor rating, candela, and decibel outputs are crucial factors that contribute to the effectiveness of an emergency notification system, especially in outdoor or public spaces where visibility and audibility are paramount. These factors are becoming consistent specification considerations for facility managers putting together their emergency notification system. Here’s how each of these factors plays a role:

Outdoor Rating:

Outdoor-rated notification devices are designed to withstand exposure to the elements, including rain, snow, UV radiation, extreme temperatures, and dust. This durability is critical for ensuring that the system remains operational during all weather conditions. Because outdoor environments can accelerate the corrosion of materials, corrosion resistant materials are often preferable. Outdoor-rated components are often made from materials that resist corrosion, ensuring the system’s long-term reliability. Additionally, outdoor-rated devices are typically built to withstand physical impact, reducing the risk of damage due to accidents, vandalism, or other factors.

Candela (cd)& Decibel (dB) Output:

Candela output measures the brightness or intensity of the light emitted by visual notification devices, such as strobe lights or beacons, while decibel output measures the intensity of sound deployed by audible notification systems. In an outdoor emergency notification system, higher candela and decibel output is essential to ensure that the visual signals are visible over long distances and in bright daylight conditions.

The ability to adjust the candela output can be important, as it allows for tailored signaling depending on the specific emergency or the audience. For example, raising the candela output or utilizing a Xenon-powered strobe can be more effective for a person with impaired hearing. Conversely, some emergency notification systems use varying decibel outputs and tones to signal different types of emergencies. This can help people distinguish between various alerts, such as fire alarms, severe weather warnings, or security incidents.

Conclusion

As technology advances, signaling industry trends in wireless solutions and LED lighting have emerged as frontrunners, offering flexibility, reliability, and cost-efficiency. Wireless systems, powered by Wi-Fi or radio, can be swiftly deployed, adapting to ever-changing needs and centralizing emergency alerts. LED lights, known for their longevity and energy efficiency, provide versatile visual signaling options, which can be critical in distinguishing between various types of emergencies. While LED is on the rise, the highest-impact flash of Xenon remains unmatched in intense scenarios.

Consistency and reliability remain key as facility managers continue to weigh these emerging trends and their specific environments. Outdoor-rated equipment, designed to withstand the harshest conditions, ensures operational reliability. Candela and decibel outputs, as measures of brightness and sound intensity, hold the key to delivering effective alerts over vast distances, even in the brightest of daylight. Customization options, like adjusting candela output and employing Xenon-powered strobes, cater to diverse audiences, including those with impaired hearing.

In this dynamic landscape, where technology and user needs intersect, a successful emergency notification system remains rooted in these core considerations. It combines the latest trends in signaling industry innovation with steadfast reliability to protect lives and assets, ensuring that the right message is heard and seen when it matters most.